4-wire Nema 34 Stepper motor, 3A, 1.8 degree, 2 phase

from

$146.77

Ex Tax: $146.77

- Stock: In Stock

- Model: SCJ009365

- SKU: SCJ009365

Products Sold: 0

Product Views: 830

Available Options

Ask a Question About This Product

- Description

4-wire Nema 34 Stepper motor, 3A, 1.8 degree, 2 phase

Brief

Nema 34 2 phase 1.8 degree per step stepper motor with excellent quality, high holding torque and low power consumption, sell by manufacturer directly.

Description

4-wire 2 phase bipolar Nema 34 stepper motor, specified to have a maximum current of 3A, resolution of 1.8 degree/step, torque of 8.4Nm.

Specifications

| Basics | Model | SOCOJE2120-3004A |

| Matched the Driver Model | SCJ009365 (Click it to see more info) | |

| Step Angle | 1.8° | |

| Length | 120mm | |

| Weight | 4kg | |

| Current | 3A | |

| Resistance | 2.3Ω | |

| Holding Torque | 8.4Nm | |

| Motor Leads | 4 | |

| Rotor Inertia | 3200g-cm2 | |

| Technical parameters | Step Angle Accuracy | ±5% (full step, no load) |

| Resistance Accuracy | ±10% | |

| Inductance Accuracy | ±20% | |

| Temperature Rise | 80℃Max. (rated current, 2 phase on) | |

| Ambient Temperature | -10℃~+50℃ | |

| Insulation Resistance | 100MΩ Min. 500VDC | |

| Dielectric Strength | 1Min. 500VAC·5mA | |

| Shaft Radial Play | 0.06Max. 450g | |

| Shaft Axial Play | 0.08Max. 450g |

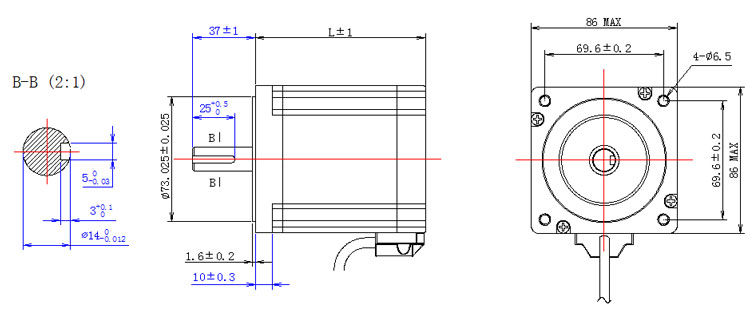

Dimension

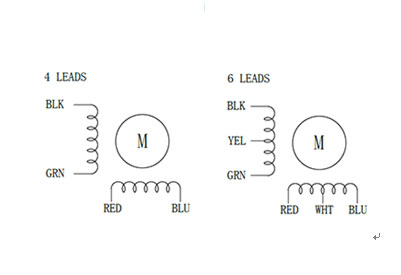

Motor Connection

Tips: The reasons why the stepping motor suddenly stops when it starts to run

If the stepper motor doesn’t rotate sometimes or motion back and forth on the spot when starting, it is generally necessary to give considerations into inspection of following aspects:

- When selecting the motor, whether the computing of working torque is large enough and can drive the load. Therefore, we generally recommend users to select the motor whose torque should be larger than actual demands by 30%-50% of. For the stepper motor cannot rotate around overloading, no matter the moment, step out will be caused. If serious, the stalling or repeated and irregular motioning on the spot will be caused.

- Whether the input stroke pulse of the upper controller is correct. Firstly, it is necessary to set 5V and 15mA to have optocoupler stably conducted, whether the frequency of input is high and it is filtered by optocoupler.

- Whether the start frequency is too high and acceleration process is set on the start procedure. It is better to begin accelerating to the set rate from the start frequency regulated for the motor. No matter the acceleration time is very short, or it cannot be stable.

- When the motor is not fixed, such situation may emerge sometimes, which belongs to the normal situation for the intense resonance of the motor is caused and it the stalling state is generated. Therefore, the motor should be fixed.

- Whether there is lack of phase, if so, the motor will joggle and cannot rotate normally. As for 2-phase stepper motor, the motor also cannot work normally in case of wrong phase.

- Reviews