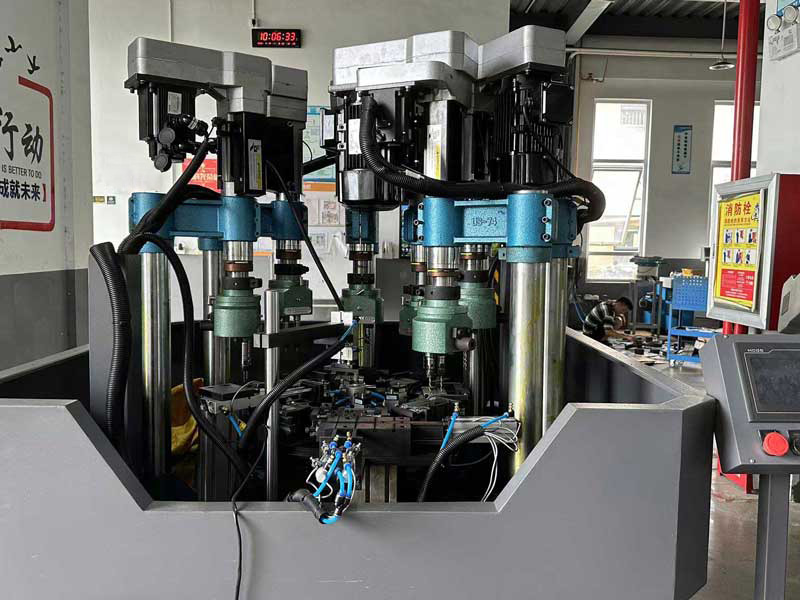

Drilling and tapping machines For Aluminum, galvanized parts, stainless steel, and other hardware accessories

from

$10,000.00

Ex Tax: $10,000.00

5 or more $8,000.00

10 or more $6,000.00

- Stock: In Stock

- Model: SCJ000189

- SKU: SCJ000189

Products Sold: 0

Product Views: 573

Available Options

Ask a Question About This Product

- Specifications

| Industry-specific attributes | |

| Type | Drilling & Milling Machine |

| Max. Drilling Dia. (mm) | 12 |

| Other attributes | |

| Condition | New |

| Range of Spindle Speed(r.p.m) | 1 - 1400 r.p.m |

| CNC or Not | CNC |

| Place of Origin | Zhejiang, China |

| Weight (KG) | 800 KG |

| Key Selling Points | Automatic |

| Showroom Location | None |

| Applicable Industries: | Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company, Other |

| Marketing Type | Hot Product 2023 |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

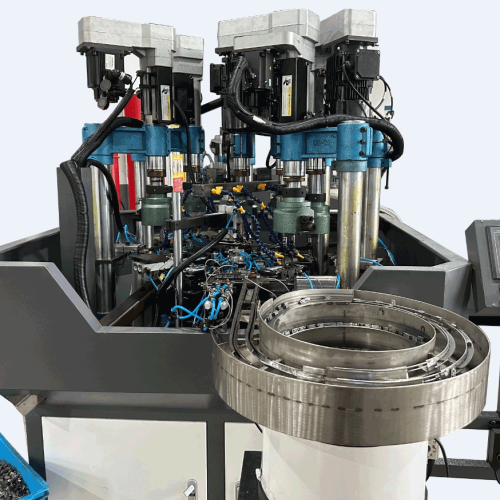

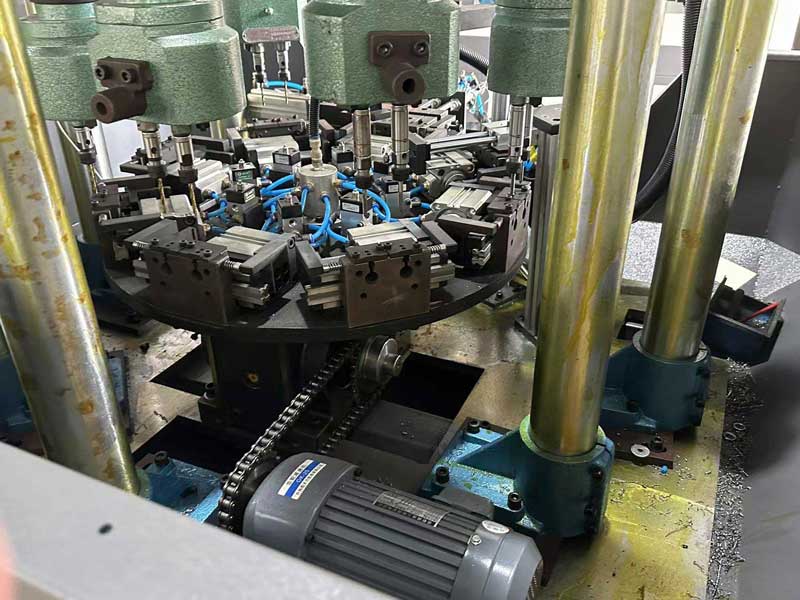

| Core Components | Bearing, Pump, Gear, Motor, Gearbox, PLC, Pressure vessel, Engine, Other |

| Drilling Speed | 1-1400r/min |

| Model Number | BZY-20 |

| Voltage | 380V/220V |

| Dimension(L*W*H) | 150*150*220mm |

| Power (kW) | 4kw |

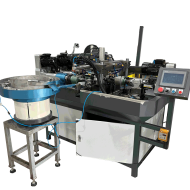

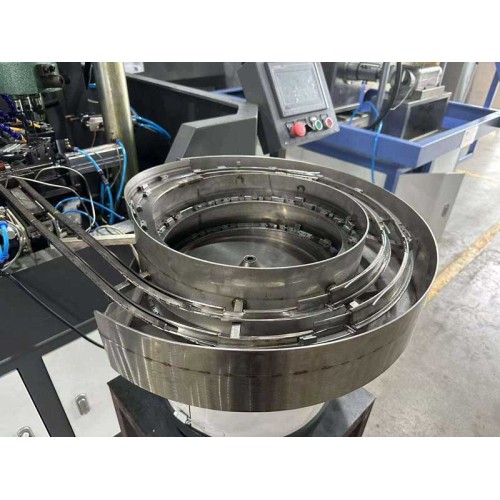

| Product name: | Multi Station Rotary Drilling Tapping Machine |

| Spindle Taper | MT.2 |

| Precision | High Precision |

| Spindle Stroke | 125mm |

| Type | Drilling Tapping Mahine |

| Max. drilling diameter | 12mm |

| column | 85mm |

| Model | BZY-20 |

| Spindle Speed(r/min) | 1-1400r/min |

| Packaging and delivery | |

| Packaging Details | Each multi station rotary drilling tapping machine is wrapped with stretch film or packed in a wooden case. |

| Port | ningbo |

| Supply Ability | |

| Supply Ability | 500 Set/Sets per Month 500sets/mon drilling machine |

- Video

- Description

Drilling and tapping machines For Aluminum, galvanized parts, stainless steel, and other hardware accessories

Product Description

1. It can complete driling, chamfering and other processes in one time to improve production efficiency.

2. Multiple processes are completed in one time, reducing clamping times, reducing the probability of product scratching, increasing product consistency, and making the product more perfect.

3. Reduce electricity consumption, energy saving and environmental protection.

4. One-button start and the general worker can also be competent.

Specification

item | value |

Condition | New |

Type | Drilling Machine |

Max. Drilling Dia. (mm) | 12mm |

Range of Spindle Speed(r.p.m) | 1r.p.m - 1400r.p.m |

CNC or Not | CNC |

Drilling Speed | 1-1400r/min |

Model Number | BZY-20 |

Voltage | 380V/220V |

Dimension(L*W*H) | 150*150*220cm |

Power (kW) | 4kw |

Weight (KG) | 800KG |

Common types of drilling tapping machine include:

Drill presses - Stationary machines that hold the workpiece in place while the drill bit rotates to create holes.

CNC (computer numerical control) drilling and tapping centers - Automated machines that can perform complex drilling and tapping operations with high precision.

Handheld power drills - Portable drills that can be used for light-duty drilling and tapping tasks.

The drilling and tapping process typically involves:

Securing the workpiece

Selecting the appropriate drill bit and tap size

Drilling the hole to the required depth

Tapping the hole to cut the internal threads

Each

multi station rotary drilling tapping

machine is wrapped with stretch film or packed in a wooden case.

- Reviews