Hydraulic Orbital Motor 200cc/rev Low speed and high torque

from

$229.75

Ex Tax: $229.75

- Stock: In Stock

- Model: SCJ009560

- SKU: SCJ009560

Products Sold: 0

Product Views: 1298

Available Options

Ask a Question About This Product

- Description

Hydraulic Orbital Motor 200cc/rev Low speed and high torque

Brief

Low speed high torque hydraulic orbital motor at affordable price. It is a spool valve motor with 200cc/r displacement, reliable operation and high efficiency, selectable flat key shaft or splined shaft, mounting flanges of 2 bolts and 4 bolts. This orbit motor can be used in parallel or series.

Description

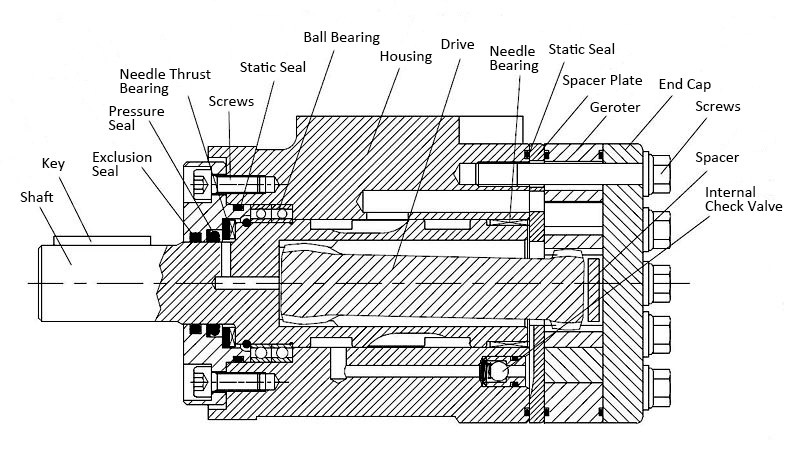

SOCOJE Hydraulic orbital motor is design of disc distribution flow, which can provide improved performance at low speed higher volumetric for the automatically compensate wear. It can be used on heavy vehicles and machinery in traction drive applications.

Specification

| Model | SCJ009560 | |

| Shaft Type (Optional) | Flat Key, Splined | |

| Flange Type (Optional) | 2 Bolts, 4 Bolts | |

| Displacement | 200 cc/rev (200 cm3/rev) | |

| Working Pressurec | 15MPa | |

| Flow | Continuous | 57 LPM |

| Intermittent | 68 LPM | |

| Max.Speed | Continuous | 284 rpm |

| Intermittent | 339 rpm | |

| Pressure | Continuous | 110 ∆Bar |

| Intermittent | 124 ∆Bar | |

| Torque | Continuous | 285 Nm |

| Intermittent | 319 Nm | |

| Weight | 8kg | |

Note:

- A simultaneous maximum torque and maximum speed is not recommended.

- ∆Bar refers to true pressure difference between inlet port and outlet port.

- Continuous Rating means that the motor may be run continuously at these ratings.

- Intermittent operation refers to that the motor running time must not exceed 10% per minute under this condition.

*To assure best orbital motor life, run it for approximately one hour at 30% of rated pressure before application to full load. Be sure this motor is filled with fluid prior to any load applications.

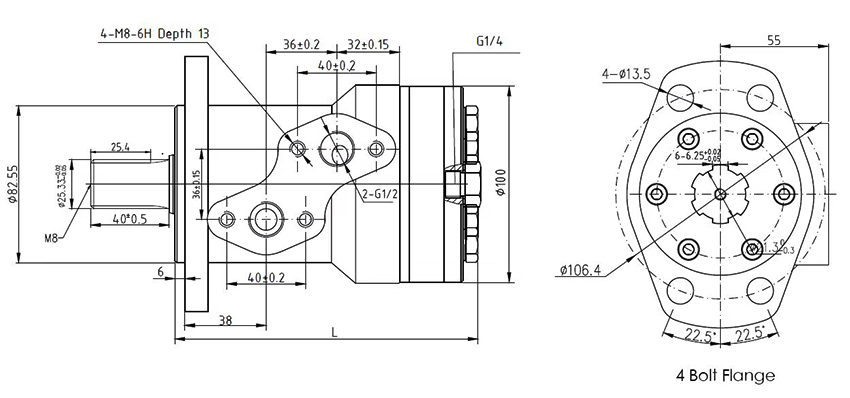

Dimensions (Unit: mm)

L1=167mm

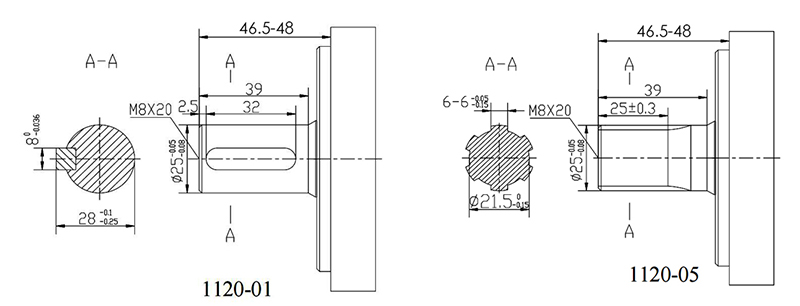

Hydraulic Orbital Motor Shaft (Unit: mm)

Flange Types (Unit: mm)

L=173mm

Details

Tips: What do you need to pay attention to when the hydraulic orbital motor fails and needs to be disassembled?

- Do not bump the joint surfaces during disassembly and assembly. If there is any bump, the hydraulic orbital motor must be repaired before assembling.

- Wash all parts with gasoline or kerosene before assembling. It is forbidden to use cotton yarn or rags to scrub the parts. Brush or silk cloth should be used. Never immerse the rubber ring in gasoline. After the orbit motor is installed, it is necessary to add 50-100 ml of hydraulic oil to the two oil ports before installing the machine, and rotate the output oil. If there is no abnormal phenomenon, the machine can be installed.

- In order to ensure the correct rotation direction of the orbital motor, pay attention to the positional relationship between the rotor and the output shaft.

- The back cover bolts must be tightened diagonally gradually with a tightening torque of 4~5 kgf.m.

- Reviews