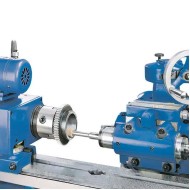

H3 Step CNC 4 Axis Automatically Metal Grinding Machine High Precision Cut Tool Grinder Machine for Cutting Tools

from

$93,300.00

Ex Tax: $93,300.00

5 or more $92,300.00

10 or more $91,300.00

- Stock: In Stock

- Model: SCJ007270

- SKU: SCJ007270

Products Sold: 0

Product Views: 253

Available Options

Ask a Question About This Product

- Specifications

| Other attributes | |

| Condition | New |

| CNC or Not | CNC |

| Place of Origin | Shanghai, China |

| Weight (KG) | 5000 |

| warranty: | 1 Year |

| Key Selling Points | CNC Step Tool Grinding Machine |

| Showroom Location | None |

| Applicable Industries: | Manufacturing Plant, Construction worksxa0, Energy & Mining, Machinery Repair Shops, Building Material Shops |

| Marketing Type | New Product 2023 |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

| Warranty of core components | 1 Year |

| Wheel Size(mm) | 250*20*31.75 |

| Core Components | Motor, Bearing, Engine, Other |

| Voltage | AC 380V |

| Clamping workpiece diameter range | 0.5-20mm |

| Dimension(L*W*H) | 2450*1980*2000mm |

| Grinding workpiece diameter range | 0.05-20mm |

| Power (kW) | 8.5/20 |

| After-sales Service Provided | Yes |

| Clamping/grinding workpiece Max. length | 300/200mm |

| Packing | Factory Standard |

| Year | 2023 |

| Rough grinding wheel size | 250*20*31.75mm |

| Rough grinding wheel speed | 0-8500 rpm (Motorized spindle) |

| Fine grinding wheel size | 150*20*31.75mm |

| Type | Tool Grinding Machine |

| Fine grinding wheel speed | 0~12000 rpm (Motorized spindle) |

| PAYMENT | T/T |

| Packaging and delivery | |

| Packaging Details | Factory ordinary packaging, please confirm with the ANTISHI for more details. |

| Port | Shanghai Port |

| Supply Ability | |

| Supply Ability | 300 Set/Sets per Month |

- Description

Product Description

H3 Step CNC 4 Axis Automatically Metal Grinding Machine Features

1.The body and components are made of mihanna high-grade cast iron fc-30, which is subjected to manual normalization heat treatment and natural aging treatment. The component processing adopts world-class equipment such as yasda, Mitsui, Seiki, Toshiba and ELB for one-time clamping and processing, and the precision size can reach micron level, so as to ensure the high precision of equipment foundation components.

2.The structure of walking center grinder, which is the first in China, makes the grinding wheel processing get rid of the problems of small grinding amount and low efficiency from the cylindrical surface. Taking the end face as the initial surface of rough machining has the advantages of large machining volume and high machining efficiency. At the same time, it has more advantages for workpieces with small diameter segment difference.The first wandering type grinder structure in China (this grinder breaks the traditional grinding method and pushes the traditional grinding method to another height)

3.The Chinese secondary development highly automatic grinding system jointly developed by our company is adopted, which can move freely and rearrange buttons and icons. The creative interface of multi-step and complex segment difference workpieces can be realized without programming. The interactive touch screen technology with excellent performance can easily realize more advanced gesture instructions

4.The operator can quickly arrange and combine the graphics according to the defined shape diagrams and the shape of the workpiece, and input relevant parameters to complete the programmed machining graphics.

5.The precision linear guide rail and precision ball screw are continuously lubricated by the automatic lubrication system to ensure longer service life and long-term optimal accuracy. The cooling and lubrication systems are separated from the body to eliminate vibration and facilitate heat dissipation.

6.The high-precision motorized spindle is selected as the grinding wheel spindle. The spindle is kept constant temperature through internal oil cooling, and a speed regulating device is installed. The maximum speed of the grinding wheel can reach 90m / s. for workpieces with different diameters, the processing is convenient and fast to ensure efficiency.

H3 Step CNC 4 Axis Automatically Metal Grinding Machine Standard Parts

ITEM | Place of Origin | Brand/Model |

CNC control system | Australia | ANCA (7 axis) |

X / Z axis feed servo motor | Australia | ANCA |

X / Z axis ball screw | Japan | THK |

collet and clamping head | Guangzhou | Hao Zhi |

Rough grinding spindle | Guangzhou | DAKE |

Fine grinding spindle | Guangzhou | DAKE |

Manipulator servo | Australia | ANCA |

End face positioning device | Japan | KEYENCE |

Full automatic oiler | Taiwan,China | Proton |

coupling | Taiwan,China | NBK |

Wear resistant material | Germany | SKC |

Water pump drive motor | Taiwan,China | Proton |

Switch button / contactor | Japan | Japan FUJI |

Belt | USA | GATES |

Oil circuit components | Taiwan,China | Zhanghua Zhenrong |

Bearing | Germany | FAG |

LED work light | Shenzhen | ONN |

Cooling water tank | Dongguan | ANTIS |

Foundation cushion block | Dongguan | ANTIS |

H3 Step CNC 4 Axis Automatically Metal Grinding Machine Installation Environment Requirement

Voltage | 380V |

Total installed power | 20KW/33KW |

Operating environment temperature | 5-40℃ |

Grinding fluid filtration method | Comprehensive filtration |

Cooling water pump | 0.25KW |

Cooling water tank | 450L |

Notice: Factory ordinary packaging, please confirm with the ANTISHI for more details.

- Reviews