High Precision Forming Machine Single Crank Mechanical Press Sheet Metal CNC Pneumatic Punching Machine

from

$10,530.00

Ex Tax: $10,530.00

3 or more $10,440.00

6 or more $10,350.00

- Stock: In Stock

- Model: SCJ006625

- SKU: SCJ006625

Products Sold: 0

Product Views: 241

Available Options

Ask a Question About This Product

- Specifications

| Other attributes | |

| Condition | New |

| Power Source | Pneumatic |

| CNC or Not | CNC |

| Place of Origin | Guangdong, China |

| warranty: | 1 Year |

| Weight (T) | 3 |

| Key Selling Points | Automatic |

| Showroom Location | India |

| Applicable Industries: | Hotels, Garment Shops, Manufacturing Plant, Machinery Repair Shops, Retail, Energy & Mining |

| Marketing Type | Ordinary Product |

| Machinery Test Report | Not Available |

| Video outgoing-inspection | Not Available |

| Warranty of core components | 1 Year |

| Core Components | Bearing, Pump, Gear, Motor, Gearbox, PLC, Pressure vessel, Engine |

| Model Number | SYA-35 |

| Voltage | Apply to your country voltage |

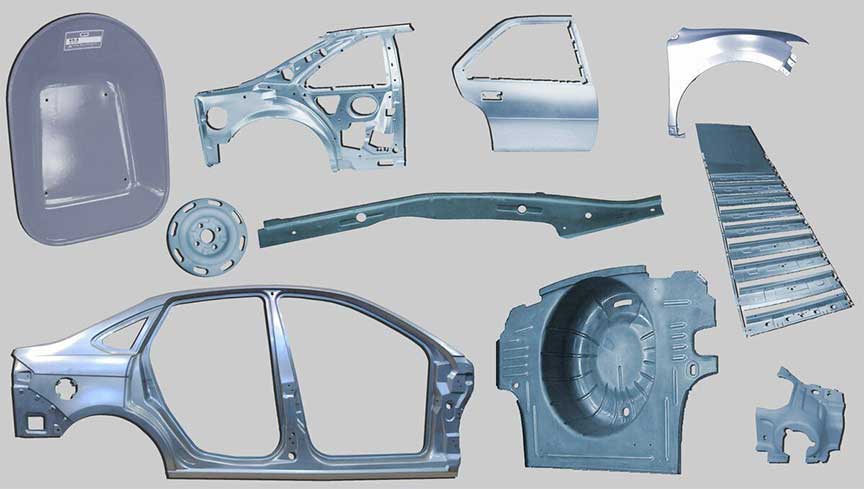

| Application Products | Buttons, Keys, License Plates, Bottle Caps, Etc. |

| Custom Type | Customized By Material, Customized By Product |

| Appropriate Types | Metal Stamping |

| Mechanical Type | Open Type |

| Product name: | Mechanical Power Punch |

| Punch Accuracy | Precision Heavy Punch |

| Machine Type | Punching Machine |

| Packaging and delivery | |

| Packaging Details | In wooden case |

- Description

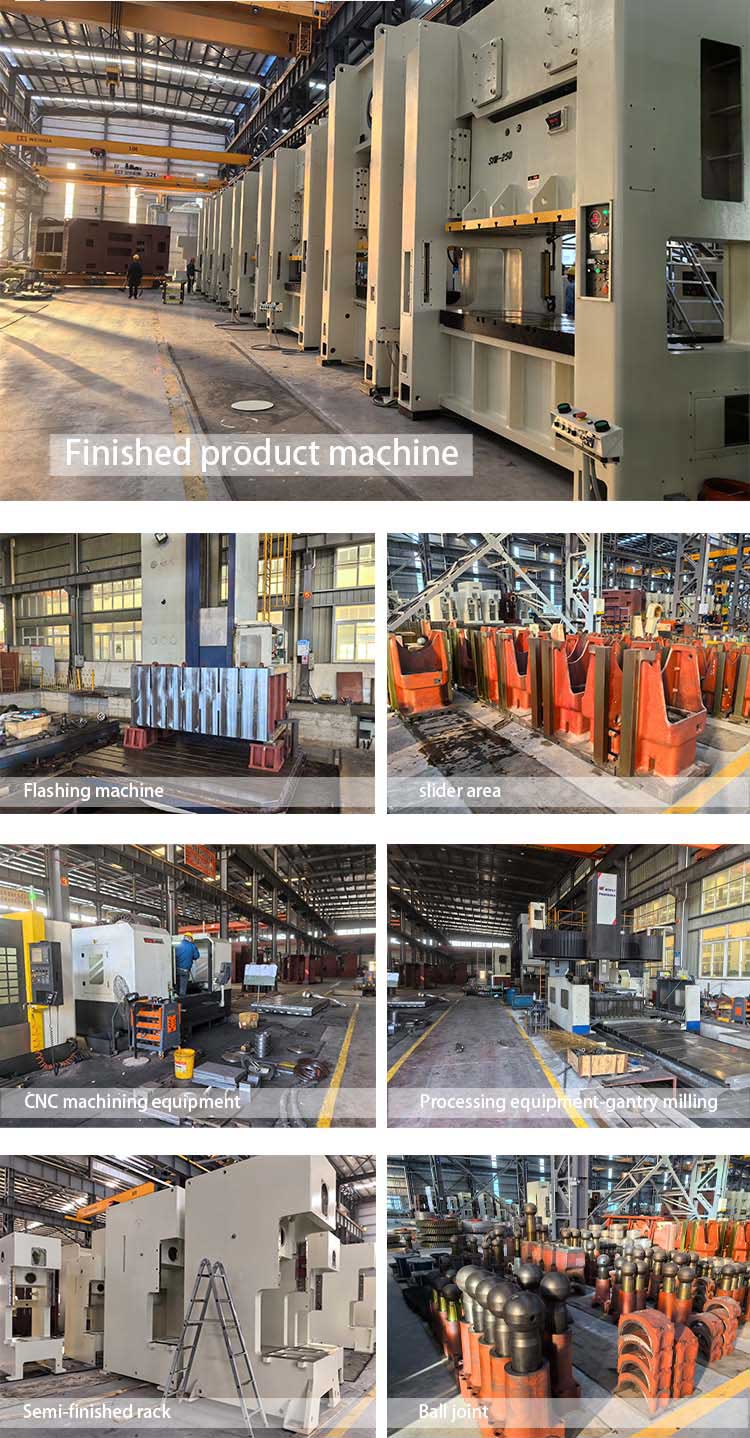

Product Description

High Precision Single Point Open Type Power Press

Pneumatic punch presses use the high-pressure gas produced by compressors to force metal into molds for wafer processing,stamping,embossing, etc.

● Steel plates welded as machine body, treated to remove internal stress, marked with high rigidity;

● Crankshaft longitudinally arranged, compact structure and beautiful outlook;

● Hexagonal guide rails of extra length, guide in high precision;

● PLC-controlled electric circuit, safety duplex valve for air pipelines, flexible and highly sensitive in movement,safe and reliable, single time, inching and continuous operations for options, conforming to the safety standard for stamping machines;

● Hydraulic overload protection device and rigid protection device to prevent damage of the machine tools due to overload;

● Combined-type pneumatic friction clutch-brake, steady engagement, low noise level;

Professional stamping automation equipment

The machine body is welded of quality and treated by tension elimination, improve stability and reliability of precision of the machine.

Crank, gear, connect bar are oxidized hardening and milled, having super comrehensive mechanical perfor-mance and durable function.

Reasonable structural design, is convenient for au-tomatic production and line production.

Used reliable high intensity clutch/brake and twin electromagnetic valve, overloading protector can guar-antee safe production all-around.

Adopt safety double solenoid valve and hydraulic overload protection device to ensure production and operation safety.

The mold bearing large impact loading as well as pressing of eccentric mold.

Adopted closed electric loop circuit, have compatible with any automatic equipments.

Main Parameter

Model | Unit | SYA-25 | SYA-35 | SYA-45 | SYA-60 | |||||||||||

V | H | V | H | V | H | V | H | |||||||||

Capacity | Ton | 25 | 35 | 45 | 60 | |||||||||||

Rated tonnage point | mm | 3.2 | 1.6 | 3.2 | 1.6 | 3.2 | 1.6 | 4 | 2 | |||||||

Stroke | mm | 70 | 30 | 70 | 40 | 80 | 50 | 120 | 60 | |||||||

Speed changing | s.p.m | 60-140 | 130-200 | 40-120 | 110-180 | 40-100 | 110-150 | 35-90 | 80-120 | |||||||

Die height | mm | 195 | 215 | 220 | 235 | 250 | 265 | 310 | 340 | |||||||

Slide adjustment | mm | 50 | 55 | 60 | 75 | |||||||||||

Slide area | mm | 470x230x50 | 520x250x50 | 560x300x60 | 700x360x70 | |||||||||||

Bolster area | mm | 680x300x70 | 800x400x70 | 850x440x80 | 900x500x80 | |||||||||||

Shank hole | mm | ∅38.1 | ∅38.1 | ∅38.1 | ∅50 | |||||||||||

Main motor | kw.p | 3.7x4 | 3.7x4 | 5.5x4 | 5.5x4 | |||||||||||

Slide adjust device | HP | 手动 manual operation | ||||||||||||||

Air pressure | kg/cm2 | 6 | ||||||||||||||

Press precision | GB/JIS 1 class | |||||||||||||||

Presses dimension | mm | 1350x930x 2200 | 1400x1050x2400 | 1600x1100x2500 | 1620x1150x2800 | |||||||||||

Die cushion capacity | Ton | - | 2.3 | 2.3 | 3.6 | |||||||||||

Stroke | mm | - | 50 | 50 | 70 | |||||||||||

Die cushion effective area | mm2 | - | 300x230 | 300x230 | 350x300 | |||||||||||

More Details

Mould

Type: Stamping press moulds (customized)

Mould Life: 30,000,000 shots,etc. (except wearing part )

Delivery time: 3 to 6 weeks

(3 weeks for prototype mold)

Sample

- Reviews