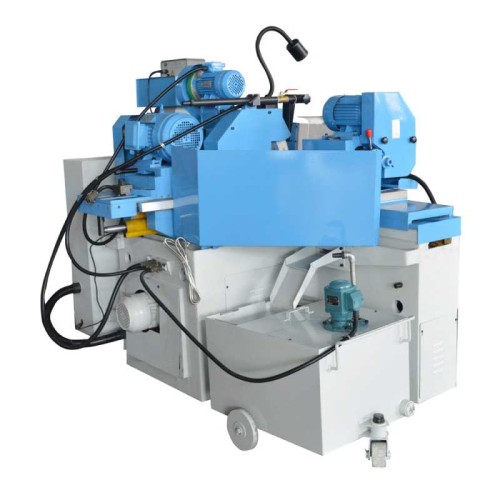

Universal Cylindrical Grinder 9-1/2 inch Swing 20-1/2 inch Distance Digital

from

$26,900.00

Ex Tax: $26,900.00

- Stock: In Stock

- Model: SCJ004396

- SKU: SCJ004396

Products Sold: 0

Product Views: 321

Ask a Question About This Product

- Specifications

| attribute-list | |

| Model: | M1420 |

| Power | Three-phase 220V 60hz 25A |

| Max. Load Between Centers | TABLE |

| Swivel Angle | +9°, -9° |

| Handwheel Feed per Rotation | 0.393"/rev. |

| Workhead Center Taper | MT#4 |

| Workhead Swivel Angle | +90º, -90º |

| Workhead Spindle Speed RPM | 63 / 125 / 250 / 500 RPM |

| Workhead Spindle Rotation | Forward & Reverse |

| Tailstock Work Center Taper | MT#4 |

| Internal Grinding Device Spindle Speed | 12250 / 14848 / 19600 RPM |

| Max. Load of Spindle | WHEELHEAD |

| Wheelhead Swivel Angle | +3°, -3° |

| Handwheel Feed per Graduation | Rough: 0.00025" Fine: 0.0001" |

| Handwheel Feed per Revolution | Rough: 0.05" |

| Internal Grinding Spindle Motor | MACHINE |

- Description

About this product

1. 1-axis position indicator

2. Distance between centers: 20-1/2"

3. Max. swiveling dia.: 9-1/2"

4. Max. external grinding length × dia.: 19-11/16" × 7-7/8"

5. Max. internal grinding depth: 4-15/16"

6. Taper MT4 and 5" Jaw chuck

7. Circulating cooling system

8. Suitable for External grinding and internal grinding

| Standard Accessories: |

| 1. Balancing mandrel |

| 2. Wheel balancing stand |

| 3. Three jaw chuck |

| 4. Internal grinding attachment |

| 5. Wheel flange |

| 6. Coolant tank |

| 7. Stand grinding wheel dresser |

1. Precision-ground guide rail ensure maximum accuracy across the entire workpiece length and accommodate high workpiece weights.

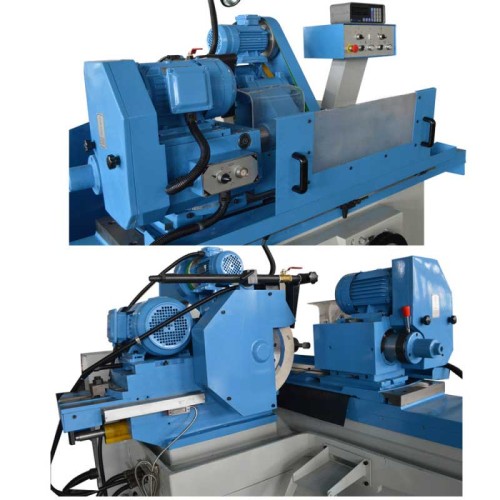

2. The adjustable grinding spindle features superior bearings and provides for maximum precision and surface quality.

3. The heavy-duty spindle head swivels 90° to the left and to the right; the work spindle head swivels 3°

4. The machine can grind the inner hole

5. Spindle of the wheel head uses the dynamic pressure bearing spindle of big-tapered telescope-feed and high-precision, which has the high rotation precision and long time maintenance.

6. Grinding wheel feed mechanism uses gear structure, which is flexible and accurate to operate.

7. The hydraulic drive system uses screw feed which is low noise.

8. The speed spindle head runs on precision bearings, assuring greater spindle stability and providing outstanding accuracy for external and internal diameter grinding and face grinding.

- Reviews