DHB150 Hydraulic Servo Drive Powerful Line Boring Machine

from

$77,260.00

Ex Tax: $77,260.00

5 or more $77,160.00

- Stock: In Stock

- Model: SCJ006910

- SKU: SCJ006910

Products Sold: 0

Product Views: 280

Available Options

Ask a Question About This Product

- Specifications

| Industry-specific attributes | |

| Table Travel (X) (mm) | 0 mm |

| Table Travel (Y) (mm) | 0 mm |

| Table Travel (Z) (mm) | 0 mm |

| Other attributes | |

| Condition | New |

| Range of Spindle Speed(r.p.m) | 155 r.p.m |

| CNC or Not | Normal |

| Place of Origin | Liaoning, China |

| Number of Axes | 2 |

| warranty: | 1 Year |

| Weight (T) | 0.5 T |

| Key Selling Points | Automatic |

| Showroom Location | Russia, Kenya, Colombia, Kazakhstan |

| Applicable Industries: | Hotels, Building Material Shops, Machinery Repair Shops, Construction worksxa0, Energy & Mining |

| warranty period | 12 Months |

| Marketing Type | New Product 2020 |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

| Warranty of core components | 1 Year |

| Core Components | Bearing |

| Production Capacity | 50-100 Sets/month |

| Voltage | 220V, 380V |

| Dimension(L*W*H) | according to bar length |

| Travel (W-axis) (mm) | 0 mm |

| After-sales Service Provided | Overseas service center available |

| Type | portable |

| Boring bar diameter | 150mm |

| Max. Table Load(kg) | 0 |

| Bore diameter | 220-1000mm |

| Boring stroke | 500-4000mm |

| Model | DHB150 |

| Product type | Portable Line Boring Machineine |

| Motor power(feed drive) | 18.Kw |

| Feed Rate | 0-0.5mm/r |

| Functions | Boring |

| Packaging and delivery | |

| Packaging Details | Wooden package suitable for long distance shipping. |

| Port | Dalian |

| Supply Ability | |

| Supply Ability | 5 Set/Sets per Month |

- Description

Product Description

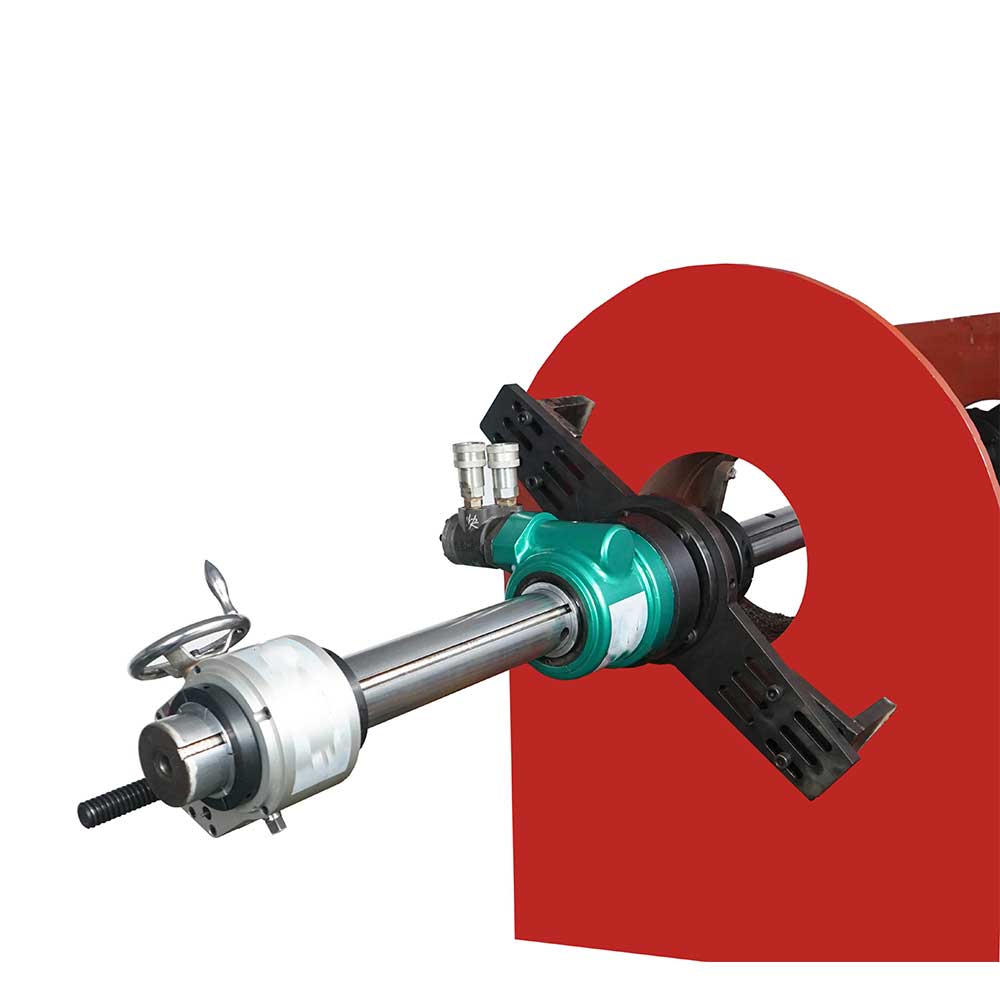

PORTABLE LINE BORING MACHINE

We are professional and skilled for producing as well as selling in this kind of machine since we have been in this area for more than 10 years. Machines are upgraded year by year, we updated the components continully to improve the quality, at the same time reduce its cost, now we have a mature system to insure customers would absolutely purchase machines with best quality and competitive price.

Heavy-duty line boring machien | ||||||||||||||

Item | Unit | DB90 | DB120 | DHB150 | DB200 | DB250 | ||||||||

voltage | V | 380V | 380V | 380V | ||||||||||

Max.diameter of boring hole | mm | 95-800 | 180-900 | 220-1000 | 380-1200 | 380-1500 | ||||||||

length of boring bar | mm | 1500/2000/3000(customized) | 1500/2000/3000 (custom made) | 1500/2000/3000(custom made) | 1500/2000 /3000/4000 | 1500/2000 /3000/4000 | ||||||||

spindle movement | mm | 500-900(customized) | 500-900(customized) | 500-4000 (custom made) | 500-4000 (custom made) | 500-4000 (custom made) | 500-4000 (custom made) | |||||||

Maximum turning amount | mm | 3 | 3 | 3 | 3 | 3 | 3 | |||||||

driver system | —— | Hydraulic | servo motor | servo motor/Hydraulic | servo motor/Hydraulic | Hydraulic | Hydraulic | |||||||

Motor power | KW | 3.5/3 | 3 | 3 | 3 | 3 | 3 | |||||||

The spindle speed | rpm/min | 100-155 | 0-80 | 62 | 55 | 38 | 38 | |||||||

Feed amount | mm/rpm | 0-0.5 | 6 | 0-0.5 | 0-0.58 | 0-0.58 | 0-0.58 | |||||||

The range of feed speed | mm/min | 0-60 | 0-90 | 0-0.05 | —— | —— | —— | |||||||

torque | N/M | 573 | 500 | 600 | —— | —— | —— | |||||||

The surface roughness | Ra | 3.2 | 3.2 | 3.2 | 3.2 | 3.2 | 3.2 | |||||||

Boring roundness error | mm | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | |||||||

The support structure | —— | One-shaped support /Tripod | One-shaped support /Tripod | One-shaped support/Tripod/T-shaped support | Quadriga | Quadriga | Quadriga | |||||||

The range of milling | mm(φ) | 120-450 | 250-850 | 130-950 | 260-1050 | 450-1300 | 480-1600 | |||||||

Machine main features:

1) The driver:3.5Kw Hydraulic/Servo motor provide enough torque,ensure that cutting process powerful and stable.

2) Feed forward and reverse can be achieved with a 1.5w motor in the electric control box.

3) Induction hardened boring bar has high wear resistance and good toughness properties.

4) You can fasten the tool holder anywhere along the boring bar.

5) Modular components make setup quick and easy.

6) Motor controller has the function of delay stopping,so when you stop,the tool will not be demaged easily.

7) With the powerful facing head,you can handle the facing jobs with ease.(Optional)

Detailed Images

Power Plugs

10A, 250V with CE standard.

Core parts

Oil-free lubrication,strong rigidity,small gap and long serve time.

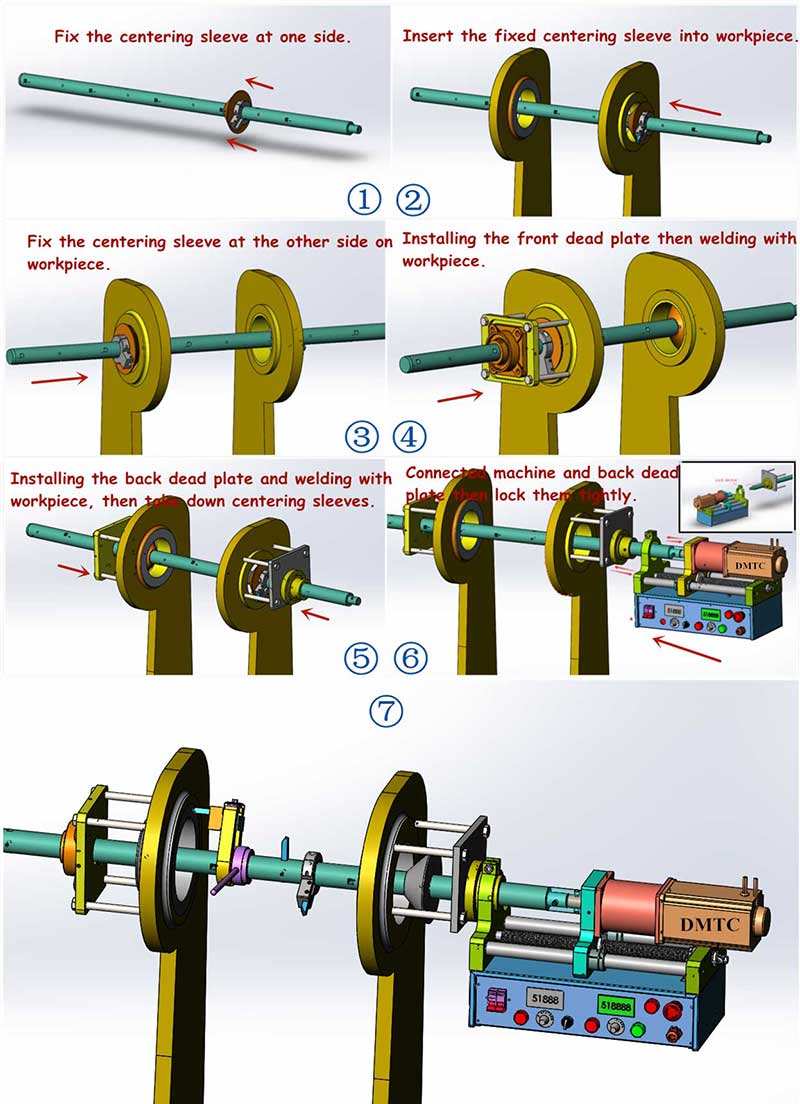

Installation Steps

Optional Accessories

AUTO-WELDING MACHINE&WELDING RESOURCE

Simple operation, perfect appearance, light volume, stable welding rotation, large welding stroke, intelligent brushless motor and intelligent drive.

Welding power supply (wire feeder + electric welding machine) can work in conjunction with automatic welding produced by our company. The changed welding power supply has stable output current, low cost and long life. It is recommended that customers choose a welding power source when purchasing automatic welding.

FACER&BORING BAR

The use of high-quality steel has the functions of smooth rotation, good processing and clean surface, and automatic feed. It is recommended that customers choose facer when purchasing boring machines.

The boring bar is made of high hardness material with smooth surface, even texture and very straight. The length and diameter of the boring bar can be customized according to the processing requirements, 40/50/60*1500-5000mm. In addition, can also be customized universal joint boring bar.

Ready To Ship

- Reviews