- Stock: In Stock

- Model: SCJ006746

- SKU: SCJ006746

Available Options

Ask a Question About This Product

- Specifications

| Other attributes | |

| Place of Origin | China |

| Weight (KG) | 20 |

| warranty: | 1 Year |

| Key Selling Points | Easy to Operate |

| Showroom Location | Malaysia |

| Applicable Industries: | Manufacturing Plant, Other |

| Marketing Type | Hot Product 2019 |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

| Warranty of core components | 1 Year |

| Core Components | PLC, Motor |

| Max. feeding length | 130mm |

| max.feeding width | 100mm |

| Material thickness | 1.5mm |

| Max.feeding S.P.M | 130MC/min |

| Fixed clamp friction | 55kg |

| Moving clamp friction | 72.5kg |

| Pneumatic Pressure | 4.5kg/cm2 |

| Air consumption | 58.6L/mm |

| Tension Force | 25.5kg |

| Type | Feeder Machine |

| Usage | Metal Sheet Strip Coil |

| Packaging and delivery | |

| Packaging Details | In wooden case |

- Description

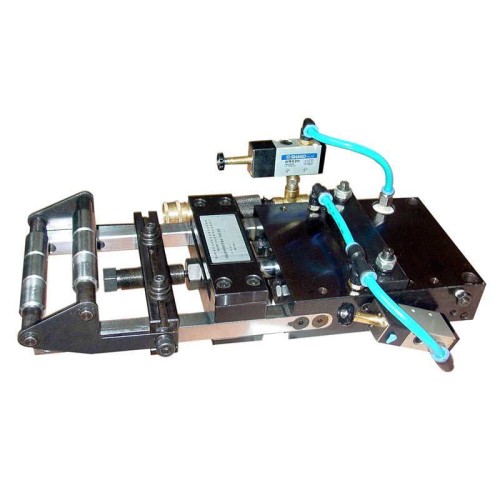

Pneumatic Feeder

We are the leading the manufacturer and supplier of all type of Pneumatic Feeder such as Air Feeder, NC Servo Roll Feeder, Mechanical Gripper Feeder, New Gripper Series, CAM Feeder, Industrial Pneumatic Feeder, Heavy Duty Pneumatic Feeder, Gear Change Feeder, Gripper Feeder, High Precision Feeder, Nc Servo Feeder, Servo Roll Feeder, Push And Pull Feeder, Band Feeders, Coil Feeder, Mechanical Plunger Actuated Feeder, Zig Zag Feeders, Nc Servo Zig Zag Feeder, Mechanical Roll Feeder, Die Feeder, Roll Feeder, Zig Zag Feeders, Mechanical Plunger Actuated Feeder, Feeders For Power Press, Feeding Machine, Roll Feeder, Die Feeder, Coil Feeder.

-Features

1. High efficiency, low friction valve, increase speed efficiency

2. All the seals are imported from Japan

3. The novel floating rod adopts a two-position three-way valve structure, the problem of easy air leakage in the position of floating rod is completely solved.

4. Low failure rate,adopts 45 degree steel by CNC finishing, so it is not easy to have problems.

5. Minimal floor area, simple structure and easy to installation.

6. The operation process is stable and the feeding accuracy is high.

7. Compact overall structure,with high precision and fast speed;all machines will go through strict test before shipping.

8. Any size and length can be customized.

Description

·Main process

11. The central hole of the main structure is by grinding firstly then electroplating , so as to better ensure its roundness and straightness, which thus enable the core shaft to run smoothly.

12. After processed, the main structure goes through anti-corrosive treatment, and then it is cleaned through ultrasonic wave before assembled so as to guarantee trouble-free when processing leftover materials.

13. The guiding rail is processed through hard chrome plating finish after going high tensile steel heating process. The connection between mobile part and guiding rail goes through accurate grinding so as to make machine moving and its motion flexible and stable.

·Fittings

11. Replaceable directional valve adopts large rounded corner structure,the inner hole is polished by mirror, which greatly improves the feeding speed of feeder and the service life of the sealing ring.

12. Adopting two sets of pneumatic buffers,it can automatically absorb the inertial impact in the process of using the air feeder, effectively reducing the vibration and noise.

13. All screws are installed with high strength press oxygen adhesive , so that they will not be loosened by the shock o of long time use, and can achieve a good sealing effect.

Air feeder type

·E type solenoid valve standard model

Suitable for short stroke of press machine, or too long feeding length.

·R type solenoid valve standard model

For high precision feeding, use electromagnetism valve to slack fixed clamp to correct error.

·Left and right zigzag style

Suitable for various forms of parts processing, can save more than 1/2 of the material. The support adopts direct bearing, cooperates with the circular rod slide, no noise, high wear resistance, light load, rapid displacement, and shorten the feeding time. Choose feeding time by electronic control. Simple operation, easy maintenance, high

Specification:

Type | Strip Width Max. | Stroke max. | Strip Thickness Max. | Max. Stroke/min |

AF-1C | 50mm | 50mm | 0.5mm | 250 |

AF-2C | 65mm | 80mm | 0.8mm | 200 |

AF-3C | 80mm | 80mm | 1.2mm | 180 |

AF-4C | 100mm | 130mm | 1.5mm | 130 |

AF-5C | 150mm | 150mm | 2.0mm | 100 |

AF-6C | 200mm | 200mm | 2.0mm | 50 |

AF-7C | 250mm | 250mm | 2.5mm | 50 |

AF-8C | 300mm | 300mm | 2.5mm | 45 |

AF-9C | 350mm | 350mm | 3.0mm | 35 |

AF-10C | 400mm | 400mm | 3.0mm | 30 |

AF-11C | 450mm | 450mm | 3.0mm | 25 |

- Reviews