- Stock: In Stock

- Model: SCJ009681

- SKU: SCJ009681

Available Options

Ask a Question About This Product

- Description

Brief

Description

Pneumatic cylinders with minimized complexity are being sold featuring customizable bore and stroke as well as other selection functions and accessories including high temperature resistance, embedded magnet and male threads. With the cylinder body constructed by aluminum alloy, the device strikes a perfect balance between durability and functionality.

Product features:

- There are magnetic switch slots around the cylinder body which is convenient to install a sensor switch.

- Multiple bore sizes paired with different stroke lengths are available.

(bore sizes: 12/16/20/25/32/40/50/63/80/100mm) - Riveted structure is adopted to connect the cylinder body and back cover, as well as piston and piston rod to make it compact and reliable.

- The seal of piston adopts heterogeneous two-way seal structure to achieve a compact size and grease storage.

- Compact size can save significantly the installation area.

- The inner diameter of the body is treated with rolling followed by the treatment of hard anodizing, delivering excellent abrasion resistance and durability.

- Additional functions and accessories are offered for customization.

Specifications:

| Model | SCJ009681 | ||||||||||

| Bore size | 12mm | 16mm | 20mm | 25mm | 32mm | 40mm | 50mm | 63mm | 80mm | 100m | |

| Acting type | Double acting | ||||||||||

| Fluid | Air (to be filtered by 40 um filter element) | ||||||||||

| Operating pressure | 0.15~1.0MPa (22~145psi) (1.5~10.0bar) | ||||||||||

| Proof pressure | 1.5MPa (215psi) (15bar) | ||||||||||

| Temperature | -20~70℃ | ||||||||||

| Speed range | Double acting: 30~500mm/s | ||||||||||

| Stroke tolerance | Stroke≤100+1.00 Stroke>100+1.50 | ||||||||||

| Cushion type | Bumper | ||||||||||

| Port size | M5 × 0.8 | 1/8″ | 1/4″ | 3/8″ | |||||||

Stroke (unit=mm):

| Bore size | Standard stroke | Max. std stroke | ||

| 12mm 16mm | Double acting | With magnet | 5 10 15 20 25 30 35 40 45 50 | 50 |

| Without magnet | 5 10 15 20 25 30 35 40 45 50 55 60 | 60 | ||

| 20mm | Double acting | With magnet | 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 | 90 |

| Without magnet | 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 100 | 100 | ||

| 25mm 32mm 40mm 50mm 63mm | Double acting | With magnet | 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 100 110 120 | 120 |

| Without magnet | 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 100 110 120 130 | 130 | ||

| 80mm 100mm | Double acting | With magnet | 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 100 110 120 | 120 |

| Without magnet | 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 100 110 120 130 | 130 | ||

Note) 1.Please contact us for other special strokes. | ||||

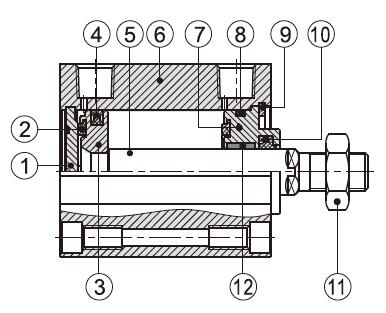

Inner structure and material of major parts:

| NO. | Item | Material |

| 1 | Back cover | No (Φ12, 16)/ Aluminum alloy (Others) |

| 2 | Bumper | NBR |

| 3 | Piston | Brass (Φ12, 16)/ Aluminum alloy (Others) |

| 4 | Piston seal | NBR |

| 5 | Piston rod | Carbon steel with 20 um chrome plated |

| 6 | Body | Aluminum alloy |

| 7 | Front cover | Aluminum alloy |

| 8 | O-ring | NBR |

| 9 | C clip | Spring steel |

| 10 | Front cover packing | NBR |

| 11 | Piston nut | Carbon steel |

| 12 | Bushing | No (Φ12~32)/ Wear resistant material (Others) |

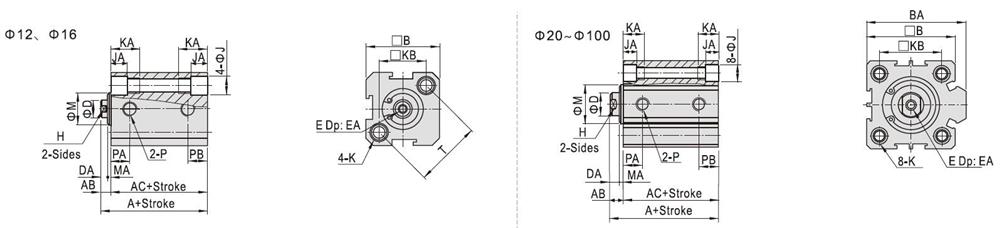

Dimensions (unit=mm):

| Item | A | AC | A | AC | AB | B | BA | D | DA | E | EA | H | J | JA | K | KA | KB | M | MA | P | PA | PB | T | ||

| Bore size | Without magnet | With magnet | St=5 | St>5 | St=5 | St>5 | |||||||||||||||||||

| 12 | 22 | 17 | 32 | 27 | 5 | 25 | - | 6 | 4 | M3×0.5 | 6 | 5 | 6.5 | 4.5 | M5×0.8Thru.hole: Φ4.2 | 12 | 16.3 | 10.2 | 1 | M5×0.8 | 7.5 | 7.5 | 5 | 5 | 23 |

| 16 | 24 | 18.5 | 34 | 28.5 | 5.5 | 29 | - | 6 | 4 | M3×0.5 | 6 | 5 | 6.5 | 4.5 | M5×0.8Thru.hole: Φ4.2 | 12 | 19.8 | 11 | 1.5 | M5×0.8 | 8 | 8 | 5 | 5.5 | 28 |

| 20 | 25 | 19.5 | 35 | 29.5 | 5.5 | 34 | 36 | 8 | 4 | M4×0.7 | 8 | 6 | 6.5 | 4.5 | M5×0.8Thru.hole: Φ4.2 | 14 | 24 | 13 | 1.5 | M5×0.8 | 8 | 9 | 5 | 5.5 | - |

| 25 | 27 | 21 | 37 | 31 | 6 | 40 | 42 | 10 | 4 | M5×0.8 | 10 | 8 | 8.2 | 5.5 | M6×1.0Thru.hole: Φ5.2 | 15 | 28 | 17 | 2 | M5×0.8 | 9 | 9 | 5.5 | 5.5 | - |

| 32 | 31.5 | 24.5 | 41.5 | 34.5 | 7 | 44 | 50 | 12 | 4.5 | M6×1.0 | 12 | 10 | 8.2 | 5.5 | M6×1.0Thru.hole: Φ5.2 | 16 | 34 | 22 | 2.5 | 1/8″ | 9 | 9 | 6.5 | 9 | - |

| 40 | 33 | 26 | 43 | 36 | 7 | 52 | 58.5 | 16 | 4 | M8×1.25 | 12 | 14 | 10.5 | 6.5 | M8×1.25Thru.hole: Φ6.7 | 20 | 40 | 28 | 3 | 1/8″ | 9.5 | 9.5 | 7.5 | 7.5 | - |

| 50 | 37 | 28 | 47 | 38 | 9 | 62 | 71.5 | 20 | 5 | M10×1.5 | 15 | 17 | 10.5 | 6.5 | M8×1.25Thru.hole: Φ6.7 | 25 | 48 | 38 | 4 | 1/4″ | 8 | 10.5 | 8 | 10.5 | - |

| 63 | 41 | 32 | 51 | 42 | 9 | 75 | 84.5 | 20 | 5 | M10×1.5 | 15 | 17 | 10.5 | 6.5 | M8×1.25Thru.hole: Φ6.7 | 25 | 60 | 40 | 4 | 1/4″ | 9.5 | 12 | 9.5 | 11 | - |

| 80 | 52 | 41 | 62 | 51 | 11 | 94 | 104 | 25 | 6 | M14×1.5 | 20 | 22 | 17 | 11 | M12×1.75Thru.hole: Φ10.4 | 25 | 74 | 45 | 5 | 3/8″ | 11.5 | 14.5 | 11.5 | 14.5 | - |

| 100 | 63 | 51 | 73 | 61 | 12 | 114 | 124 | 32 | 7 | M18×1.5 | 20 | 27 | 19 | 13 | M14×2.0Thru.hole: Φ12.4 | 30 | 90 | 55 | 5 | 3/8″ | 16 | 20.5 | 16 | 20.5 | - |

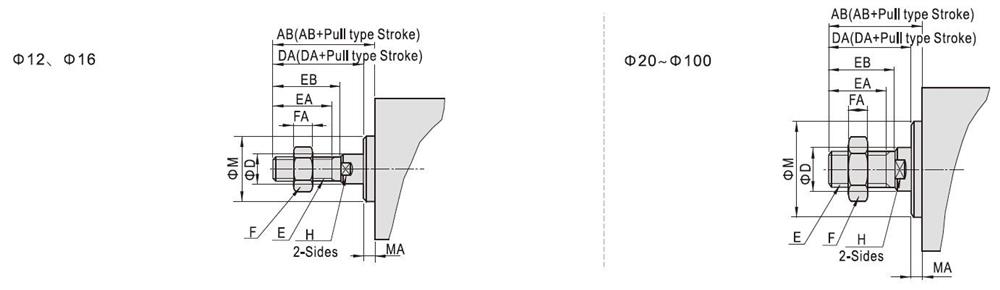

Male thread

| Bore size/Item | AB | D | DA | E | EA | EB | F | FA | H | M | MA |

| 12 | 17 | 6 | 16 | M5×0.8 | 10 | 12 | 8 | 4 | 5 | 10.2 | 1 |

| 16 | 17.5 | 6 | 16 | M5×0.8 | 10 | 12 | 8 | 4 | 5 | 11 | 1.5 |

| 20 | 20.5 | 8 | 19 | M6×1.0 | 13 | 15 | 10 | 5 | 6 | 13 | 1.5 |

| 25 | 23 | 10 | 21 | M8×1.25 | 15 | 17 | 12 | 6 | 8 | 17 | 2 |

| 32 | 25 | 12 | 22 | M10×1.25 | 15 | 18 | 17 | 6 | 10 | 22 | 2.5 |

| 40 | 35 | 16 | 32 | M14×1.5 | 25 | 28 | 19 | 8 | 14 | 28 | 3 |

| 50 | 37 | 20 | 33 | M18×1.5 | 25 | 28 | 27 | 11 | 17 | 38 | 4 |

| 63 | 37 | 20 | 33 | M18×1.5 | 25 | 28 | 27 | 11 | 17 | 40 | 4 |

| 80 | 44 | 25 | 39 | M22×1.5 | 30 | 33 | 32 | 13 | 22 | 45 | 5 |

| 100 | 50 | 32 | 45 | M26×1.5 | 35 | 38 | 36 | 13 | 27 | 55 | 5 |

Note: Optional function of high temperature resistance, embedded magent and male threaded types are offered with extra charges for your customization, and the price list is presented below.

| Bore size Extra rates | 12mm | 16mm | 20mm | 25mm | 32mm | 40mm | 50mm | 63mm | 80mm | 100mm |

| Stroke length plus 10mm | $1.23 | $1.23 | $1.38 | $1.54 | $1.85 | $2.31 | $2.77 | |||

| High temperature resistance | $1.08 | $1.08 | $1.23 | $1.54 | $1.85 | $2.15 | $2.46 | $3.08 | $3.69 | $4.92 |

| With magnet | $0.77 | $0.77 | $0.77 | $0.77 | $0.92 | $1.23 | $1.54 | $1.85 | $2.31 | $3.08 |

| Male threaded type | $0.46 | $0.46 | $0.46 | $0.46 | $0.46 | $0.46 | $0.77 | $0.77 | $1.08 | $1.54 |

Tips: Precautions for installation and application of pneumatic cylinders

- When load changes in the work, the cylinder with abundant output capacity shall be selected.

- Cylinders with high temperature resistance or corrosion resistance shall be chosen under the condition of the high temperature or corrosion.

- Necessary protection measures shall be taken in the environment with higher humidity, much dust or water drops, oil dust and welding dregs.

- Dirty substances in the pipe must be eliminated before cylinder is connected with pipeline to prevent the ingress of particles into the cylinder.

- The medium used by cylinder shall be filtered to 40 um or below.

- As both of the front cover and piston of the cylinder are short, typically too long stroke can not be selected.

- Anti-freezing measures shall be adopted under low temperature environment to prevent moisture freezing.

- The cylinder shall avoid the influence of side load in operation to maintain the normal work of cylinder and extend the service life.

- If the cylinder is dismantled and stored for a long time, please conduct anti-rust treatment to the surface. Anti-dust caps shall be added in air inlet and outlet ports. The front and back cover can not be dismantled, which shall be especially noticed.

- Reviews