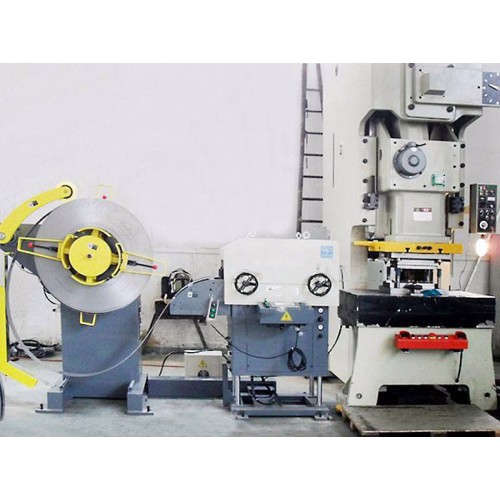

Hydraulic Pneumatic Hole Press Key Cutting Automatic Blanking Machine Components Application Of Punching Machine

from

$10,000.00

Ex Tax: $10,000.00

- Stock: In Stock

- Model: SCJ006660

- SKU: SCJ006660

Products Sold: 0

Product Views: 232

Available Options

Ask a Question About This Product

- Specifications

| Other attributes | |

| Condition | New |

| Power Source | motor |

| CNC or Not | CNC |

| Place of Origin | Guangdong, China |

| warranty: | 1 year |

| Weight (T) | 200 |

| Key Selling Points | High-accuracy |

| Showroom Location | Malaysia |

| Applicable Industries: | Manufacturing Plant |

| Marketing Type | Hot Product 2019 |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

| Warranty of core components | 1 Year |

| Core Components | Bearing, Gear, Motor, PLC, Engine |

| Model Number | JH21 |

| Voltage | 220v, 380v, 415v, customized |

| Capacity | 15T |

| Dimension(L*W*H) | 1000mmx1000mmx1900mm |

| After-sales Service Provided | Engineers available to service machinery overseas |

| Product name: | Automatic Blanking Machine Components Application Of Punching Machine |

| Precision | GB(JIS)1class |

| Slide Stroke | 60mm |

| Application | Metal Sheet Stamping |

| Machine Type | Punching Machine |

| SPM | 130 |

| Max Die Set Height | 200mm |

| Keyword: | Mechanical Metal Punching Machine |

| Packaging and delivery | |

| Packaging Details | Hydraulic Pneumatic Hole Press Key Cutting Automatic Blanking Machine Components Application Of Punching Machine |

| Port | Shenzhen |

| Supply Ability | |

| Supply Ability | 30 Unit/Units per Month |

- Description

Product Description

Performances and characteristics

1. Steel plates welded as machine body, treated to remove internal stress,marked with high rigidity;

2.Crankshaft longitudinally arranged, compact structure and beautiful outlook;

3. Hexagonal guide rails of extra length, guide in high precision;

4.Combined-type pneumatic friction clutch-brake, steady engagement, low noise level;

5.Hydraulic overload protection device for JH21 and rigid protection device for JF21 to prevent damage of the machine tools due to overload;

6.PLC-controlled electric circuit, safety duplex valve for air pipelines, flexible and highly sensitive in movement, safe and reliable, single time, inching and continuous operations for options, conforming to the safety standard for stamping machines.

| Model | JH21-25 | JH21-45 | JH21-60 | JH21-80 | JH21-125 | JH21-160 | JH21-200* | JH21-200 | JH21-250 | JH21-315 | JH21-400 | ||

| Nominal force | KN | 250 | 450 | 600 | 800 | 1250 | 1600 | 2000 | 2000 | 2500 | 3150 | 4000 | |

| Stroke of nominal force | mm | 3 | 4 | 4 | 5 | 5 | 6 | 6 | 6 | 7 | 7 | 8 | |

| Stroke of sliding block | mm | 80 | 120 | 140 | 160 | 180 | 200 | 180 | 250 | 250 | 250 | 280 | |

| Number strokes | min | 100 | 80 | 70 | 60 | 50 | 45 | 35 | 45 | 40 | 30 | 30 | |

Maximun height for die loading | mm | 250 | 270 | 300 | 320 | 350 | 400 | 390 | 450 | 500 | 500 | 530 | |

Adjustment range for die loading height | mm | 50 | 60 | 70 | 80 | 90 | 100 | 110 | 110 | 120 | 120 | 120 | |

Distance from slid block centre to the frame | mm | 210 | 225 | 270 | 310 | 350 | 390 | 390 | 430 | 450 | 450 | 480 | |

Space between columns | mm | 450 | 500 | 560 | 620 | 660 | 720 | 870 | 900 | 980 | 980 | 1000 | |

Bottom size of sliding block | Left-right | mm | 360 | 410 | 480 | 540 | 620 | 700 | 800 | 880 | 950 | 950 | 1000 |

| Front-back | mm | 250 | 340 | 400 | 460 | 520 | 580 | 600 | 650 | 700 | 700 | 750 | |

Hole size for die handle | Diameter | mm | 40 | 50 | 50 | 50 | 70 | 70 | 70 | 70 | 70 | 70 | 70 |

| Depth | mm | 65 | 60 | 60 | 90 | 90 | 100 | 90 | 100 | 100 | 100 | 100 | |

Size of worktable | Left-right | mm | 700 | 810 | 870 | 950 | 1070 | 1170 | 1400 | 1390 | 1500 | 1540 | 1700 |

| Front-back | mm | 400 | 440 | 520 | 600 | 680 | 760 | 760 | 840 | 880 | 880 | 940 | |

| Thickness | mm | 80 | 110 | 130 | 140 | 155 | 160 | 160 | 180 | 190 | 190 | 200 | |

| Blank-holding hole | mm | 150 | 150 | 150 | 150 | 160 | 180 | 200 | 200 | 200 | 200 | 250 | |

Distance from worktable to ground | mm | 780 | 800 | 900 | 900 | 900 | 900 | 1000 | 1000 | 1000 | 1000 | 1000 | |

Distance of ground bolts | Front-back | mm | 835 | 950 | 1100 | 1235 | 1510 | 1660 | 2020 | 2020 | 2150 | 2150 | 2500 |

| Left-right | mm | 690 | 745 | 840 | 920 | 1040 | 1140 | 1360 | 1360 | 1460 | 1500 | 1550 | |

| Main motor capacity | kw | 2.2 | 5.5 | 5.5 | 7.5 | 11 | 15 | 15 | 15 | 22 | 30 | 37 | |

| Press Dimension | Front-back | mm | 1346 | 1435 | 1685 | 2125 | 2355 | 2380 | 2580 | 2585 | 2820 | 2880 | 3150 |

| Left-right | mm | 945 | 1075 | 1200 | 1760 | 1875 | 1450 | 1690 | 1690 | 1710 | 1750 | 1790 | |

| height | mm | 2120 | 2391 | 2570 | 3040 | 3255 | 3250 | 3810 | 3810 | 3900 | 3920 | 4610 | |

| Weight | kg | 2700 | 3800 | 5300 | 6600 | 10500 | 12800 | 20500 | 20500 | 23900 | 26800 | 3300 | |

- Reviews