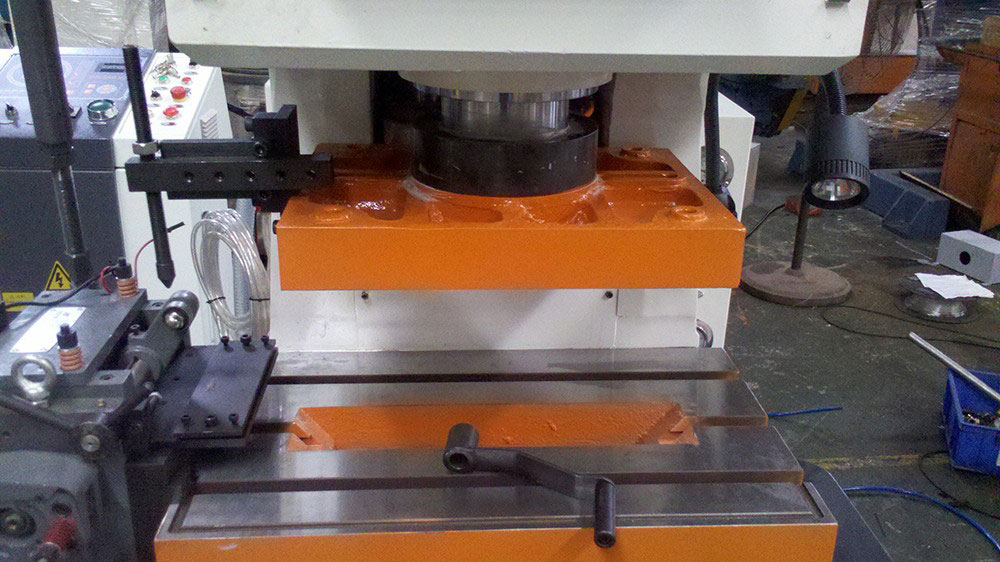

automatic snap jeas rivet eyelets stamping machines steel sheet punch press machine

from

$18,000.00

Ex Tax: $18,000.00

- Stock: In Stock

- Model: SCJ006651

- SKU: SCJ006651

Products Sold: 0

Product Views: 246

Available Options

Ask a Question About This Product

- Specifications

| Other attributes | |

| Condition | New |

| Power Source | Pneumatic |

| CNC or Not | Normal |

| Place of Origin | Guangdong, China |

| warranty: | One Year |

| Weight (T) | 14 |

| Key Selling Points | Multifunctional |

| Showroom Location | Malaysia |

| Applicable Industries: | Manufacturing Plant |

| Marketing Type | Hot Product 2019 |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Not Available |

| Warranty of core components | 1 Year |

| Core Components | Bearing, Gear, Motor, Gearbox, PLC, Pressure vessel, Engine |

| Power | 2.6X6 |

| Model Number | C-45 |

| Voltage | 380V/220V Optional |

| Capacity | 45T |

| Dimension(L*W*H) | 1420mm x1100mm x 2440mm |

| Product name: | manufacturing stamping |

| Slide Stroke | 20mm |

| Usage | Metal Press |

| Application | Metal Sheet Stamping |

| Function | Metal Processing |

| Machine Type | Hydraulic Press |

| Keyword: | automatic snap jeas rivet eyelets making machinary machine |

| Weight | 4852KG |

| Certificate: | ISO9001 |

| Packaging and delivery | |

| Packaging Details | Wooden case, automatic snap jeas rivet eyelets making machinary machine |

| Port | Shenzhen |

| Supply Ability | |

| Supply Ability | 10 Unit/Units per Month |

- Description

Product Description

Product Features

1. Body material: used with high strength casting, hard chrome plated to make sure of high precision.

2. Lubrication system: special structure with automatic closed lubrication, special industrial design so those main bodies, get quicker and more natural cooling.

3. High precision processing equipment, strict processing guarantee, many kinds of filtration system to make sure of coefficient of kinetic friction <0.03.

4. Equipped with reverse dynamic balanced device to realize high speed operation and prolong useful life of main parts.

5. Microcomputer control system: display working status and fault. Top dead center control to remove fault easily.

6. Air pressure system: use with standard parts to make system stable.

7. Adjustment mould operation control system, separate structure and function to be safer, stable and precision.

8. For main system (air, lubrication and air pressure locked) equipped with pressure show and pressure switch protector device to make all system more stable.

9. Use with force cooling circulation system in the main parts to prefect transfer mechanism, meanwhile prolong useful.

10. Equipped with location direction for direction device to be more precision, easy test and repair.

2. Lubrication system: special structure with automatic closed lubrication, special industrial design so those main bodies, get quicker and more natural cooling.

3. High precision processing equipment, strict processing guarantee, many kinds of filtration system to make sure of coefficient of kinetic friction <0.03.

4. Equipped with reverse dynamic balanced device to realize high speed operation and prolong useful life of main parts.

5. Microcomputer control system: display working status and fault. Top dead center control to remove fault easily.

6. Air pressure system: use with standard parts to make system stable.

7. Adjustment mould operation control system, separate structure and function to be safer, stable and precision.

8. For main system (air, lubrication and air pressure locked) equipped with pressure show and pressure switch protector device to make all system more stable.

9. Use with force cooling circulation system in the main parts to prefect transfer mechanism, meanwhile prolong useful.

10. Equipped with location direction for direction device to be more precision, easy test and repair.

.

Model | C-45 | ||

Capacity | 45T | ||

Stroke of slide | 20mm | 30mm | 40mm |

SPM | 200-800 | 200-700 | 200-600 |

Die-Height | 210-240mm | ||

Bolster | 7000x430x95mm | ||

Area of slide | 450x340mm | ||

Slide adjustment | 30mm | ||

Bed opening | 100mmx400mm(500mm) | ||

Motor | 7.5KWx4/380V | ||

Gross weight | 4852KG | ||

Lubrication | Forceful Automation | ||

Lubricate electrical engineering | 1/4HPx4P/380V | ||

Detailed Images

Machine Parts

Name: worktable

SIZE: 700mm(length) x 430mm(width) x 95mm(Thickness)

Original: China

Machine Parts

Name: Electric Cabinet

Brand: ESTUN

Original: ChIna

Machine Parts

Name: Shut height adjust

Die Height:210-240mm

Original: China

Optional parts

Name: Air cushion

Shape: Square/Circle

Original: China

This is optional part, pls tell us when you place order.

Our Service

- Reviews