11 kW AC Servo Spindle Motor, 70 Nm, 1500 rpm, 3-Phase

from

$2,249.69

Ex Tax: $2,249.69

- Stock: In Stock

- Model: SCJ009179

- SKU: SCJ009179

Products Sold: 0

Product Views: 1123

Available Options

Ask a Question About This Product

- Description

11 kW AC Servo Spindle Motor, 70 Nm, 1500 rpm 3-Phase

Brief

Competitive price AC servo spindle motor with 70 Nm high torque. Industrial-grade power 11 kW, rated voltage 3-phase 380V, working speed 1500 rpm, max 6000 rpm, equipped with photoelectric encoder. Asynchronous servo motor controls CNC machine spindle, matched controller and brake resistor is provided.

Description

3 phase AC servo spindle motor for sale online. Working power 11 kW, power supply 380V, max speed 6000 rpm, high torque 70 Nm, built-in high speed photoelectric encoder. The AC asynchronous servo motor can be used with a driver and brake resistor. It is widely applied in CNC machine, milling tool, woodworking router and industrial automation machine, etc.

Basic Specifications

- Model: -250ZJY-4-11-15

- Rated Power: 11 kW

- Rated Torque: 70 Nm

- Rated Voltage: AC 3-Phase 380V±15%

- Rated Speed: 1500 rpm

- Max Speed: 6000 rpm

- Rated Frequency: 50Hz

- Weight: 101 kg

Technical Parameters

- Number of Poles: 4

- Rotor Inertia: 0.014 G.D2

- Incremental Encoder Line: 2500PPR

- Installation Method: Flange installation

- Fan Power: 75W

- Fan Voltage: AC 380V

- Insulation Class: F

- Safety Class: IP54

- Insulation and Voltage Resistance: AC 1500V, 1 minute

- Insulation Resistance: DC 500V, 10M above

- Work System: Continuous

Features

- The AC servo spindle motor is a 3-phase AC induction servo motor, compact structure, small size, high torque.

- AC servo spindle motor adopts best electromagnetic design, high-speed photoelectric encoder, high precision bearings and F level insulation.

- AC servo spindle motor is in easy use, stable operation, high control precision, low electromagnetic noise, high efficiency, long service life and high performance price ratio.

- AC servo spindle motor is widely used in digital control machine, laser machine, milling machine, embroidery machine, textile machinery, printing machinery, packaging machinery, engraving machine, winding machine, three-coordinates measuring machine, industrial robot, medical equipment, woodworking router and other CNC machine.

Installation Dimension (Unit: mm)

Vertical Installation:

Horizontal Installation:

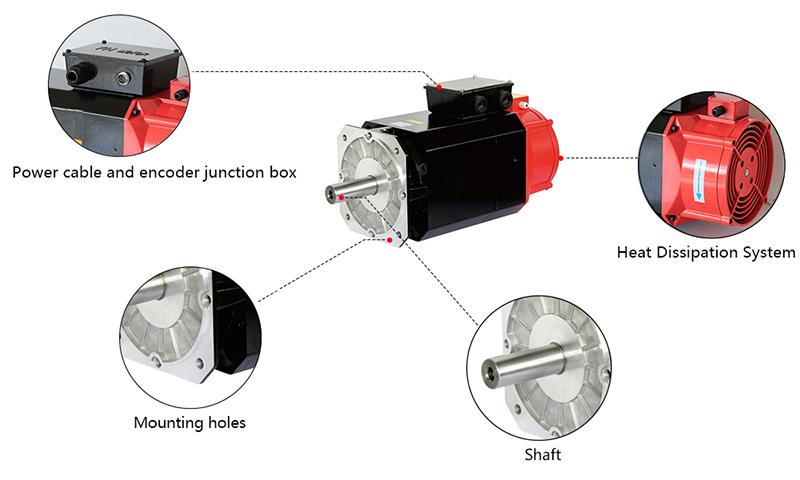

Details

Tips: Difference between a servo spindle motor and a torque motor.

- Servo spindle motor: It can make the control speed and position accuracy very accurate. Servo spindle motor can convert the voltage signal into torque and speed to drive the control object. Speed of the servo spindle motor rotor is controlled by the input signal and can react quickly. In the automation control system, servo spindle motor is used as an actuator. It has the characteristics of small electromechanical time constant, high linearity, and starting voltage.

- Torque motor: It is a special motor with a large number of poles, which can continue to run at low speeds or even when the motor is locked (that is, the rotor cannot rotate) without causing damage to the motor. In this working mode, the motor can provide a stable torque to the load.

- Reviews