5.5 kW AC Servo Spindle Motor, 35 Nm, 1460 rpm

from

$1,174.77

Ex Tax: $1,174.77

- Stock: In Stock

- Model: SCJ009176

- SKU: SCJ009176

Products Sold: 0

Product Views: 1078

Available Options

Ask a Question About This Product

- Description

5.5 kW AC Servo Spindle Motor, 35 Nm, 1460 rpm

Brief

Powerful AC servo spindle motor works at 5.5 kW rated power. Working voltage three phase 220V/380V, rated speed 1460 rpm (maximum 6000 rpm), high torque 35 Nm, high-speed photoelectric encoder. AC asynchronous servo spindle motor with economical price. Controller and brake resistor for optional configuration.

Description

Buy AC servo spindle motor at ideal price from manufacturer directly. Rated power 5500W, voltage 3-phase 220V/380V, maximum speed 6000 rpm, high torque 35 Nm. The electric motor is asynchronous servo motor, which is especially for CNC machine tool spindle control and industrial automation speed control. Built-in encoder is a high speed photoelectric encoder. Matching a driver and brake resistor is recommended.

Basic Specifications

- Model: SOCOJE-204ZJY-4-5.5-15-X

- Rated Power: 5.5 kW

- Rated Torque: 35 Nm

- Rated Voltage: AC 3-Phase 380V / 220V (Optional)

- Rated Current: 11.5A

- Rated Speed: 1460 rpm

- Max Speed: 6000 rpm

- Rated Frequency: 50Hz

- Weight: 61 kg

Technical Parameters

- Number of Poles: 4

- Rotor Inertia: 0.18 G.D2

- Incremental Encoder Line: 1024PPR / 2500PPR (Optional)

- Installation Method: Flange installation

- Fan Power: 75W

- Fan Voltage: AC 380V

- Insulation Class: F

- Safety Class: IP54

- Insulation and Voltage Resistance: AC 1500V, 1 minute

- Insulation Resistance: DC 500V, 10M above

- Work System: Continuous

Features

- The AC servo spindle motor is a 3-phase AC induction servo motor, compact structure, small size, high torque.

- AC servo spindle motor adopts best electromagnetic design, high-speed photoelectric encoder, high precision bearings and F level insulation.

- AC servo spindle motor is in easy use, stable operation, high control precision, low electromagnetic noise, high efficiency, long service life and high performance price ratio.

- AC servo spindle motor is widely used in digital control machine, laser machine, milling machine, embroidery machine, textile machinery, printing machinery, packaging machinery, engraving machine, winding machine, three-coordinates measuring machine, industrial robot, medical equipment, woodworking router and other CNC machine.

Installation Dimension (Unit: mm)

Vertical Installation:

Horizontal Installation:

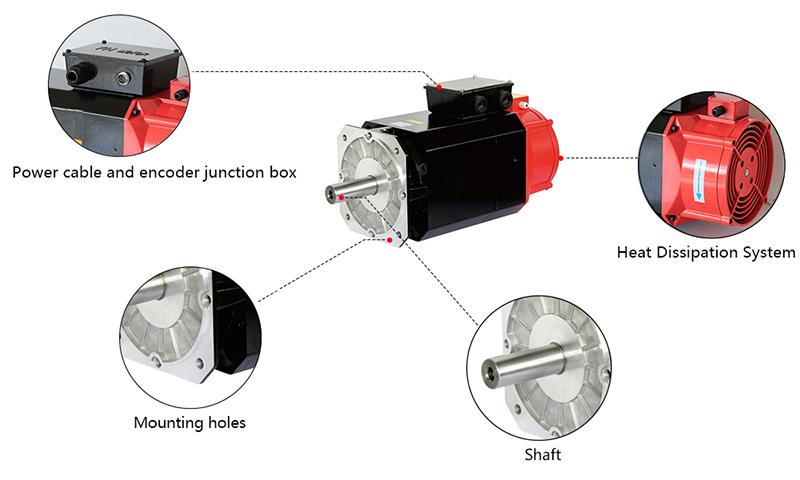

Details

Tips: Causes of vibration failure in AC servo spindle motor.

- Load inertia. The setting of load inertia is generally related to the size of the load. Excessive load inertia parameters will cause the system to vibrate. Generally, the AC servo spindle motor can automatically measure the load inertia of the system.

- Speed proportional gain. The larger the setting value, the higher the gain and the greater the rigidity of the system. The parameter value is determined according to the specific servo drive model and load condition. Generally, the greater the load inertia, the greater the set value. When the system does not produce vibration, the set value should be as large as possible. But the larger the gain, the smaller the deviation, the more easily the AC servo spindle motor will vibrate.

- Speed integral constant. Generally, the greater the load inertia, the greater the set value. When the system does not produce vibration, the set value should be as small as possible. However, reducing the integral gain will slow the response of the AC servo spindle motor and deteriorate the rigidity.

- Position proportional gain. The larger the setting value, the higher the gain and the greater the stiffness. Under the same frequency command pulse condition, the smaller the position lag, the too large the value may cause the AC servo spindle motor to vibrate.

- Acceleration feedback gain. When the AC servo spindle motor is not rotating, a small offset will be amplified by the proportional gain of the speed loop. The speed feedback generates the corresponding torque, which makes the AC servo spindle motor jitter back and forth.

- Reviews