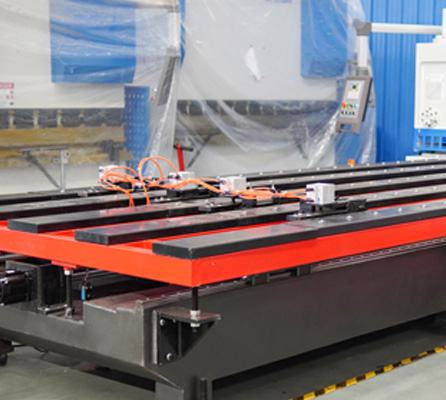

Steel 2500MM Guillotine Shearing Machine For Sheet Metal

from

$12,800.00

Ex Tax: $12,800.00

3 or more $10,000.00

5 or more $9,900.00

- Stock: In Stock

- Model: SCJ006578

- SKU: SCJ006578

Products Sold: 0

Product Views: 144

Available Options

Ask a Question About This Product

- Specifications

| Industry-specific attributes | |

| Max. Cutting Width (mm) | 2500 |

| Max. Cutting Thickness (mm) | 10 mm |

| Other attributes | |

| Automatic Level | Semi-automatic |

| Condition | New |

| Place of Origin | Jiangsu, China |

| Weight (KG) | 7300 KG |

| warranty: | 1 Year |

| Key Selling Points | High Productivity |

| Showroom Location | None |

| Applicable Industries: | Building Material Shops, Machinery Repair Shops, Construction worksxa0, Energy & Mining |

| Marketing Type | Ordinary Product |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

| Warranty of core components | 1 Year |

| Core Components | Bearing |

| Shearing Angle | 30-1°30 |

| Blade Length (mm) | 1300 mm |

| Backgauge Travel (mm) | 1 - 500 mm |

| Throat Depth (mm) | 150 mm |

| Voltage | customized |

| Dimension(L*W*H) | 3200*1700*2150 |

| Power (kW) | 11 kW |

| Year | 2023 |

| Name | Hydraulic Guillotine Shears |

| Packaging and delivery | |

| Packaging Details | Container |

| Port | Nanjing |

| Supply Ability | |

| Supply Ability | 50 Set/Sets per Month |

- Description

Products Description

HARSLE Guillotine Shearing Machine with ELGO P40

1.The streamlined welded Guillotine Shearing Machine structure achieves high rigidity.

2.The motors for backgauge are controlled by servo motor, which can achieve high accuracy and fast speed.

3.Top blade with four cutting edges and bottom blade with four cutting edges (6CrW2Si).

4.Knife gap and cutting angle can be programmed by CNC Controller ELGO P40 only by inputting material thickness.

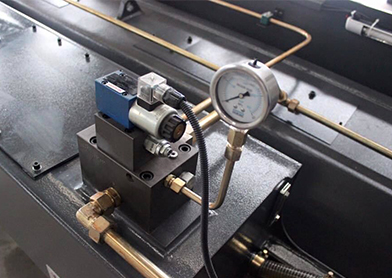

5.Hydraulic overload can be protected by overflow valve, knife rack returns by Nitrogen cylinders.

6.Foot switch with emergency button can stop the CNC cutting machine immediately when accident happens.

7.CNC Hydraulic shearing machine with Multi-Language controller operational interface will be easy for customers from all over the world.

8.Front arms with ruler and roll balls can ensure the cutting accuracy and feed the material easily.

Product Details

P40 Controller

■ LCD Display

■ Multi-Language

■ Manual inching function

■ Single set operation

■ Program memory

■ Made in Germany

■ Cutting angle and knife gap control

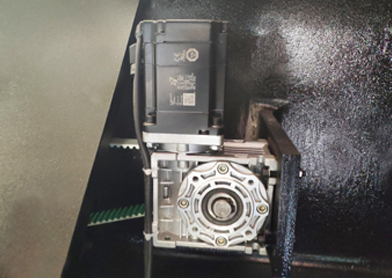

SIEMENS Motor

German famous brand motor improves the lifespan of the machine and keeps the machine working in low noise environment.

FIRST Pump

American world famous brand for hydraulic pump performs well and provides great power for the whole hydraulic system.

KACON Foot Switch

South Korea brand food switch is movable and can stop the machine anytime by the emergency button.

Front Arms

Roller ball is instACalled on the arm with ruler can reduce the abrasion and feeder the machine easily and accurately.

Open Door Power off Switch

The machine will stop immediately once worker opens the door electric cabinet.

Motorized Blade Clearance Adjustment

Adjust the cutting blades gap by motor according the cutting thickness of the metal sheet can get better cutting

performance.

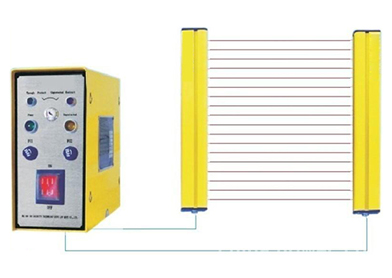

Safety Fence

Protective guards on each side can protect the user during operation.

Cutting Blade

Upper blade with 4 cutting edges, bottom blade with 4 cutting edges.

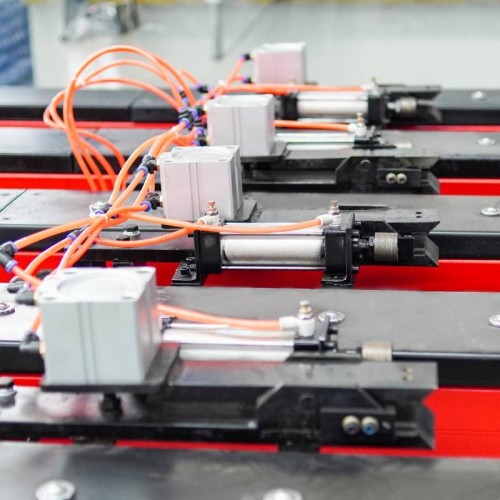

Servo Motor

Backgauge are controlled by YASKAWA servo motor with high accuracy and fast speed.

Rexroth Valve

World famous brand REXROTH, Sub-brand of BOSCH, which

is the professional hydraulic valve supplier.

Pneumatic Back Supporter(Optional)

Light Curtain(Optional)

Front Feeding Table(Optional)

Feeding the metal sheet automatically controlled by CNC controller with high precision and efficiency.

Installation Instructions

No. | Item | Unit | Quantity(In total) |

1 | Cutting blade | set | 1 |

2 | Fromt support arms | piece | 3 |

3 | Foot switch | piece | 1 |

4 | O-ring and combination gasket | set | 1 |

5 | Foundation bolts | set | 1 |

6 | Oil gun | piece | 1 |

7 | Allen wrench | set | 1 |

8 | Nitrogen inflation tool | set | 1 |

9 | Operation Manual | copy | 1 |

Manufacturing Technique

Cutting

Lathe

Milling

Drilling

Welding

Boring

- Reviews