- Stock: In Stock

- Model: SCJ009434

- SKU: SCJ009434

- UPC: 747851311311

Available Options

Ask a Question About This Product

- Description

Nema 17 Stepper motor, 6V 0.8A, 1.8 degree, 2 phase 4 wires

Brief

Description

17 stepper motor, 2 phase 4 wires bipolar stepper motor, resolution of 1.8 degree/step, torque of 36 oz/inch, high quality and brand new.

Specifications

| Electrical Specification | Model | SOCOJE39-0804A |

| Matched the Driver Model | SCJ009434 (Click it to see more info) | |

| Step Angle | 1.8° | |

| Holding Torque | 2.59kg-cm(36oz-in) | |

| Voltage | 6V | |

| Rated Current/phase | 0.8A | |

| Phase Resistance | 7.5Ω | |

| Inductance | 7.5mH | |

| Rotor Inertia | 54g-cm2 | |

| Physical Specification | Frame Size | 42 x 42mm |

| Length | 39mm | |

| Shaft Diameter | Φ5mm | |

| Shaft Length | 22mm | |

| Motor Leads | 4 | |

| Weight | 0.28kg | |

| Technical Parameters | Step Angle Accuracy | ±5% (full step, no load) |

| Resistance Accuracy | ±10% | |

| Inductance Accuracy | ±20% | |

| Temperature Rise | 80℃ Max. (rated current, 2 phase on) | |

| Ambient Temperature | -10℃~+50℃ | |

| Insulation Resistance | 100MΩ Min. 500VDC | |

| Dielectric Strength | 1Min. 500VAC·5mA | |

| Shaft Radial Play | 0.06Max. 450g | |

| Shaft Axial Play | 0.08Max. 450g | |

| Quality Assurance | Warranty Period | 12 months |

| Certificate | CE, ROHs, ISO/SGS9001 |

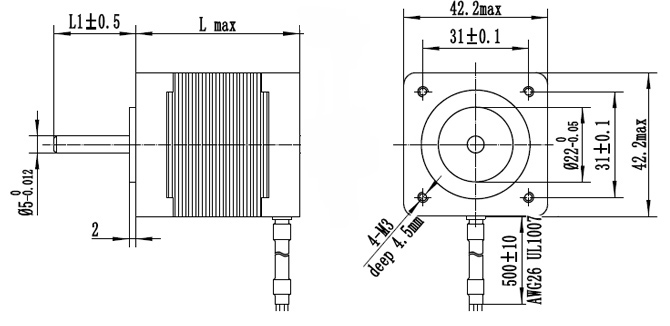

17 Stepper Motor Dimension (Unit=mm)

L1=24mm, Lmax= 39mm

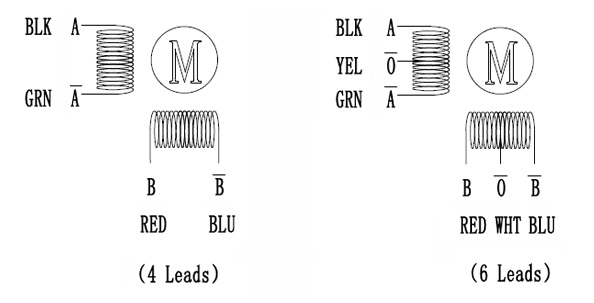

17 Stepper Motor Wiring Diagram

Tips: Current chopping drive method of stepper motor

Tips: Current chopping drive method of stepper motor

Current chopping drive is the stepper motor winding current value converted into A certain percentage of the voltage, and the comparison between the D/A converter output preset, compare the results to control the switch to power tube, so as to achieve the purpose of the control winding current.

Advantages: Make the characteristics of the movement control simulation sine waves, greatly improve the performance, speed and noise is small, can use higher segmentation, is the current popular control method.

Weakness: The circuit is more complex, the circuit is difficult to control and the theory of interference fit requirement, the prone to jitter, formed in the control of sine wave peaks and troughs, easily lead to the high frequency interference, resulting in driving element fever or aging due to high frequency, which is easy to appear when a lot of drive to use more than a year the main reason for the red light protection.

- Reviews