Nema 23 2-phase Stepper Motor, 1A, 1.8 degree, 6 wires

from

$65.46

Ex Tax: $65.46

- Stock: In Stock

- Model: SCJ009401

- SKU: SCJ009401

Products Sold: 0

Product Views: 699

Available Options

Ask a Question About This Product

- Description

Nema 23 2-phase Stepper Motor, 1A, 1.8 degree, 6 wires

Brief

Cheap stepper motor, 1A, 1.35Nm holding torque, 1.8 deg. step angle (200 steps/rev), size in Nema 23, new motor in perfect working condition and manufacturer direct sale.

Description

Nema 23 Stepper motor, 1.35Nm in 76mm, 1.8 degree, 2 phase 6 wires.

Specification

| Electrical Specification | Model | SOCOJE57STH76-1006 |

| Matched Driver Model | SCJ009401(Click it to see more info) | |

| Step Angle | 1.8° | |

| Holding Torque | 1.35Nm | |

| Rated Current/phase | 1A | |

| Phase Resistance | 8.6Ω | |

| Inductance | 14mH | |

| Rotor Inertia | 440g-cm2 | |

| Physical Specification | Frame Size | 57 x 57mm |

| Length | 76mm | |

| Shaft Diameter | Φ6.35mm | |

| Shaft Length | 19mm | |

| Motor Leads | 6 | |

| Weight | 1.1kg | |

| Technical Parameters | Step Angle Accuracy | ±5% (full step, no load) |

| Resistance Accuracy | ±10% | |

| Inductance Accuracy | ±20% | |

| Temperature Rise | 80℃ Max. (rated current, 2 phase on) | |

| Ambient Temperature | -20℃~+50℃ | |

| Insulation Resistance | 100MΩ Min. 500VDC | |

| Dielectric Strength | 500V AC for one minute | |

| Shaft Radial Play | 0.02Max. 450g | |

| Shaft Axial Play | 0.08Max. 450g | |

| Quality Assurance | Warranty Period | 12 months |

| Certificate | CE, ROHs, ISO/SGS9001 |

Nema 23 Stepper Motor Dimensions: (Unit=mm)

L Max=76mm

L Max=76mm

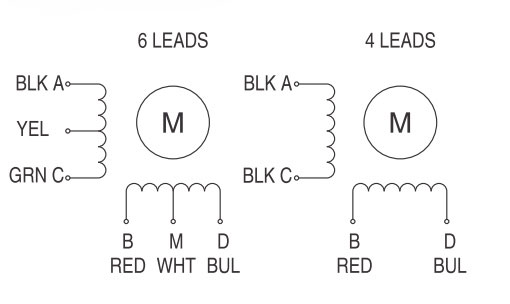

Nema 23 Stepper Motor Wiring Diagram

Tips: Differences between DC brushless and stepper motors

- The rotational velocity of DC brushless motor is higher than that of the stepper motor.

- The drive principle of DC brushless motor is different from that of stepper motor. DC brushless motor controls rotation by relying on the AC power provided by Hall element positioning while the stepper motor is directly driven by relying on single pulse voltage. Without Hall element positioning, the accurate positioning of rotational angle can be realized by controlling the number of pulses added to the motor.

- Based on different drive principles, DC brushless motor is generally applied into the occasion without high control precision requirement but the stepper motor into that with high control precision requirement.

- Reviews