Nema 23 Stepper Motor, 2 Phase, 3.5A, 2.2N·m

from

$100.99

Ex Tax: $100.99

- Stock: In Stock

- Model: SCJ009390

- SKU: SCJ009390

Products Sold: 0

Product Views: 660

Available Options

Ask a Question About This Product

- Description

Nema 23 Stepper Motor, 2 Phase, 3.5A, 2.2N·m

Brief

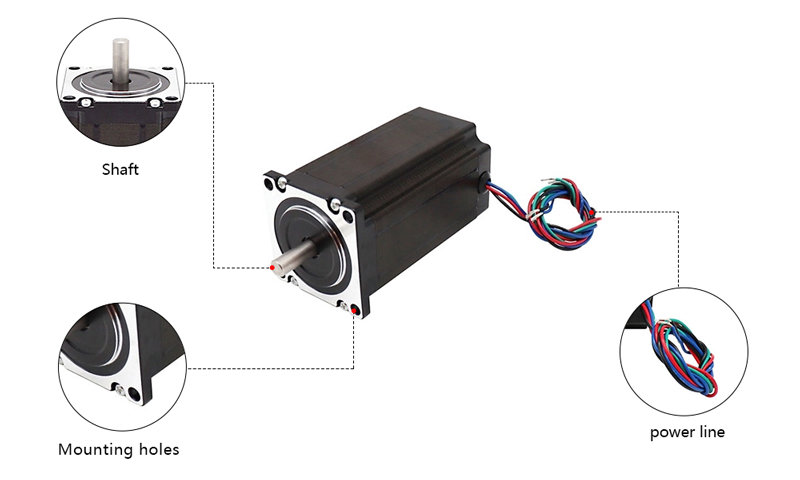

High torque Nema 23 hybrid stepper motor for sale, 3.5A, holding torque at 2.2N·m, 2 phase 4 lead wires, shaft size of 8mm and 6.35mm available, motor length 82mm. This permanent magnet stepper motor is used in 3D printer, CNC machine, robot arm and other mechanical equipment, low noise and.

Description

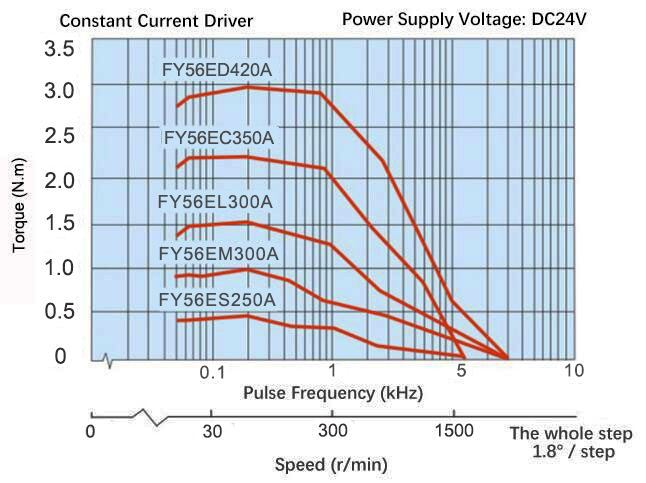

Nema 23 bipolar stepper motor used in CNC machine, drawing equipment and sewing machine, robot arm and so on. It is a four-wire connection motor with encoder, wire colors of black, green, red and blue, holding torque at 2.2N·m, step angle accuracy ±5%, no lost step and high precision. SOCOJE cheap stepper motor can be controlled by a voltage of DC 24V ~ 50V or AC 20V ~ 40V digital stepper controller for precise position control.

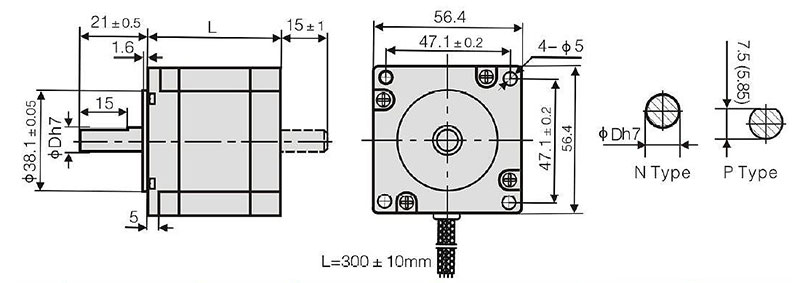

Physical Specification

- Model Number: SOCOJE-FY56EC350A

- Matched the Driver Model: ATO-FYDM504T

- Flanged Size: 57 x 57mm (Nema 23)

- Motor Length: 82mm

- Shaft Diameter: 8mm/ 6.35mm

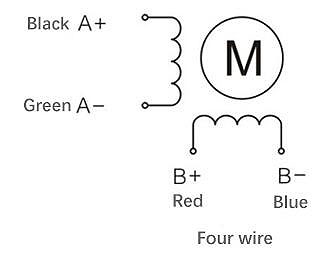

- Number of Leads: 4 wire

- Weight: 1.2kg

Electrical Specification

- Motor Type: Bipolar Stepper

- Step Angle: 1.8°

- Rated Current: 3.5A

- Holding Torque: 2.2 N·m (220 N·cm, 311.5 Oz.in)

- Phase Resistance: 0.9Ω

- Phase Inductance: 3mH

- Rotor Inertia: 520g·cm2

Dimensions (Unit: mm)

L=82mm

Wiring Diagram

Speed-Torque Curve Diagram

Details

Tips: What do you need to know about stepper motor?

- The stepper motor is used in low-speed occasions-the speed does not exceed 1000 revolutions per minute, and it is best to use between 150-450 RPM, which is most beneficial to the optimized operation and function of the motor. If you want to achieve this kind of control in the use of the motor, you can make the motor work here through the deceleration device, and keep it in this state. When the motor is used, it can achieve high work efficiency, the noise generated is also very low, and the overall performance is relatively good.

- The stepping motor is best not to use the full-step state, because the vibration generated during operation will be relatively large. Once the motor's vibration is large, it may cause noise pollution and aggravate the loss of related parts of the motor in daily use, so that the running performance of the motor will gradually deteriorate, and the service life will be shortened to a certain extent.

Documents

- Reviews