- Stock: In Stock

- Model: SCJ009406

- SKU: SCJ009406

Available Options

Ask a Question About This Product

- Description

Nema 23 Bipolar Stepper Motor, 1A, 1.8 degree, 4 wires

Brief

Description

Nema 23 bipolar Stepper motor, 0.55Nm in 41mm, 1.8 degree, 2 phase and 4 wires.

Specification

| Electrical Specification | Model | SOCOJE57HS41-1004 |

| Matched Driver Model | SCJ009406(Click it to see more info) | |

| Step Angle | 1.8° | |

| Holding Torque | 0.55Nm | |

| Rated Current/phase | 1A | |

| Phase Resistance | 5.4Ω | |

| Inductance | 9.5mH | |

| Rotor Inertia | 120g-cm2 | |

| Physical Specification | Frame Size | 57 x 57mm |

| Length | 41mm | |

| Shaft Diameter | Φ8mm | |

| Shaft Length | 19mm | |

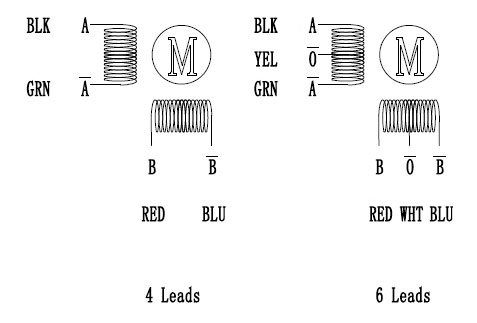

| Motor Leads | 4 | |

| Weight | 0.45kg | |

| Technical Parameters | Step Angle Accuracy | ±5% (full step, no load) |

| Resistance Accuracy | ±10% | |

| Inductance Accuracy | ±20% | |

| Temperature Rise | 80℃ Max. (rated current, 2 phase on) | |

| Ambient Temperature | -20℃~+50℃ | |

| Insulation Resistance | 100MΩ Min. 500VDC | |

| Dielectric Strength | 500V AC for one minute | |

| Shaft Radial Play | 0.02Max. 450g | |

| Shaft Axial Play | 0.08Max. 450g | |

| Quality Assurance | Warranty Period | 12 months |

| Certificate | CE, ROHs, ISO/SGS9001 |

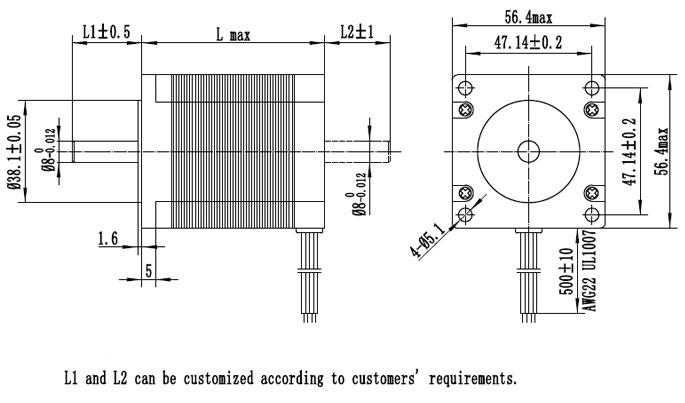

Dimensions: (Unit=mm)

L Max=41mm, Shaft Length=L1-1.6mm, L1(Common)=20.6mm

Wiring Diagram

Tips: Velocity characteristic of stepper motor

The rotational velocity of the stepper motor depends on pulse frequency, number of teeth and beats of rotor. Its angular velocity is in direct proportion to the pulse frequency. Meanwhile, the time synchronizes with the pulse. Therefore, under the circumstance that there is certain number of teeth and beats of teeth of rotor, the necessary velocity can be obtained by only controlling the pulse frequency. As the stepper motor is started by relying on its synchronic torque. To avoid step out, start frequency is not high. Especially, along with the increase in power, the diameter of the rotor increases and so does the inertia. The difference between start frequency and maximum operating frequency might be more than 10 times.

To make full use of the rapid performance of motor, the motor is generally started at low frequency lower than the start frequency, and then the pulse frequency is increased gradually until the expected velocity is reached. To choose the change rate, it is necessary to ensure the step out doesn’t occur and acceleration time should be shortened as far as possible. To ensure the positioning accuracy of the motor, the velocity of the motor should be gradually reduced to the velocity (equal to or larger than the start velocity) at which the motor can stop from the maximum velocity.

- Reviews