- Stock: In Stock

- Model: SCJ009385

- SKU: SCJ009385

Available Options

Ask a Question About This Product

- Description

Nema 24 Stepper Motor, 4A, 1.8 degree, 2 phase 4 wires

Brief

Description

Nema 24 Stepper motor, 1.8 degree, 2.5Nm in 88mm, phase current 4A and resistance 0.3Ω.

Specification

| Basics | Model | SOCOJE288-4004A |

| Matched Driver Model | SCJ009385(Click it to see more info) | |

| Holding torque | 2.5Nm | |

| Current/phase | 4A | |

| Resistance | 0.3Ω | |

| Step angle | 1.8 ° | |

| Rotor inertia | 1600g.cm² | |

| Weight | 2.4kg | |

| Length | 88mm | |

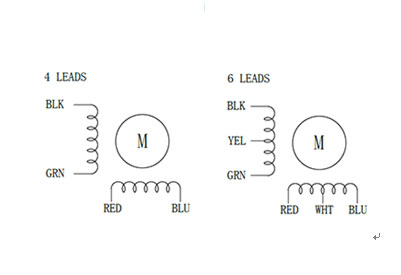

| Motor leads | 4 | |

| Technical parameters | Step Angle Accuracy | ±5%(full step, no load) |

| Resistance Accuracy | ±10% | |

| Inductance Accuracy | ±20% | |

| Temperature Rise | 80℃ Max.(rated current, 2 phase on) | |

| Ambient Temperature | -10℃~+ 50℃ | |

| Insulation Resistance | 100MΩ Min 500V DC | |

| Dielectric Strength | 500V AC for one minute | |

| Shaft Radial Play | 0.06Max.(450g) | |

| Shaft Axial Play | 0.08Max.(450g) |

Dimensions

Motor Connection

Tips: Application of stepper motor in paper rewinding machine

Paper rewinding machine, an indispensable machine in printing industry, plays a key role in pharmaceutical industry. It is used for rewinding a large piece of aluminum foil paper overlapped in single row into a reel. It is controlled with programmable controller. By using stepper motor and air cylinder as actuating elements, it features stable and reliable action, simple operation, convenient maintenance and automatic running. It can automatically give alarm and stop working when there is no paper or the fed paper is little. The contact part between tablet and the machine is made of 304 materials while the other part is made of steel plate stoving varnish, 304 or aluminum alloy anodizing. It is a most ideal device tablet reel of the pharmaceutical factory and such similar packages.

Composition and functions:

- Tablet feeding part: the tablets are put into the hopper, the oscillator will automatic feed the tablets into the table sequencing part. The feeder of this part and the tablet sequencing is automatic. When there are many tablets, it will stop feeding tablets, and vice versa.

- Tablet sequencing part: The role of this part is to arrange the disordered tablets according to certain direction and set quantity and feed them into the tablet feeding part.

- Paper feeding part: putting the packing material into the location of roll paper, then the machine will automatically feed the tablets into the film rolling location.

- Electric control part: the whole operation process of the device is controlled through PLC, and automatically actuated according to the sequence. In case of lack of certain package, it will automatically give alarm and halt down.

- Reviews