Nema 34 Hybrid Stepper Motor, 3A, 1.2 degree, 3 phase 6 wires

from

$148.46

Ex Tax: $148.46

- Stock: In Stock

- Model: SCJ009382

- SKU: SCJ009382

Products Sold: 0

Product Views: 671

Available Options

Ask a Question About This Product

- Description

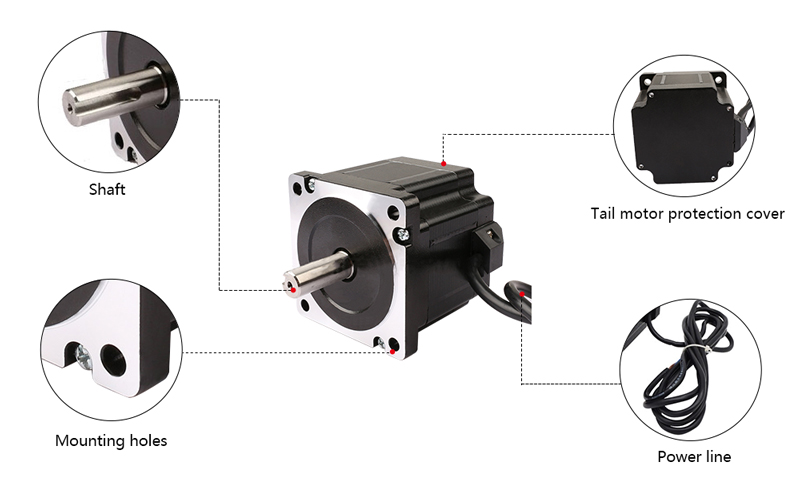

Nema 34 Hybrid Stepper Motor, 3A, 1.2 degree, 3 phase 6 wires

Brief

Nema 34 Hybrid Stepper motor with high torque, 5.4 Nm holding torque, body in 96mm long, 1.2 deg. step angle, widely applied in printing machine, industrial automation, etc. Brand new and manufacturer direct sale.

Description

Nema 34 Stepper motor, 5.4Nm holding torque, 3A phase curent, 1.2° step angle.

Specification

| Basics | Model | SOCOJE3096-3006A |

| Matched Driver Model | SCJ009382(Click it to see more info) | |

| Holding torque | 5.4Nm | |

| Current/phase | 3A | |

| Resistance | 1.74Ω | |

| Step angle | 1.2° | |

| Rotor inertia | 2200g.cm² | |

| Weight | 2.8kg | |

| Length | 96mm | |

| Motor leads | 6 | |

| Technical parameters | Step Angle Accuracy | ±5%(full step, no load) |

| Resistance Accuracy | ±10% | |

| Inductance Accuracy | ±20% | |

| Temperature Rise | 80℃ Max.(rated current, 2 phase on) | |

| Ambient Temperature | -10℃~+ 50℃ | |

| Insulation Resistance | 100MΩ Min 500V DC | |

| Dielectric Strength | 500V AC for one minute | |

| Shaft Radial Play | 0.06Max.(450g) | |

| Shaft Axial Play | 0.08Max.(450g) |

Dimensions

Motor Connection

Details

Tips: Selection of the stepper motor: how to select stepper motor driver?

- Constant voltage drive is generally only applicable for the rotation at the velocity lower than 150rpm and under the circumstance of large batch and low cost. What is further common is constant current drive.

- Besides good high velocity holding torque, the rotational smoothness of the motor with constant current drive can be improved through subdivision of driver. Firstly, it is necessary to match drive voltage and current and subdivision number. If the working speed is not low, the subdivision number is generally between 1/8~1/64. Partial torque of subdivision part will be lost. Subdivision is mainly for rotational smoothness, the uniformity at each step after subdivision cannot be guaranteed.

- According to the requirement of structural arrangement, integrated stepper motor connecting the stepper motor with the driver can be selected.

- As for the superior driver, besides good product quality coherence and stability, better performance in smoothness of rotation at low velocity and torque of rotation at high velocity should also be made.

- As for high voltage driver, under the circumstance that input power voltage stability is not high enough, the strong and weak current of the drive should completely separate.

- To make full use of stepper motor, certain margin should be left for the current of the driver under the circumstance that the torque margin of the stepper motor is very little.

- Reviews