- Stock: In Stock

- Model: SCJ001619

- SKU: SCJ001619

Available Options

Ask a Question About This Product

- Specifications

| Industry-specific attributes | |

| Type | Center Drill Bit, Core Drill Bit, Countersink Drill Bit, Gun Drill Bit, Indexable Drill Bit, Spade Drill Bit, Twist Drill Bit |

| Finish | Black Oxide, ZINC, Plain |

| Use | Metal Drilling |

| Other attributes | |

| Place of Origin | Zhejiang, China |

| Use | Metal Drilling |

| Working Length (mm) | 10 |

| Model Number | C-twist drill |

| Type | Twist Drill Bit |

| Usage | High Speed Cutting |

| Application | Drilling Holes |

| Advantage | Long Working Life |

| Material | HIGH SPEED STEEL |

| MOQ | 10 Pcs |

| Color | Silver |

| Packaging and delivery | |

| Packaging Details | The cobalt twist drills set shall be carefully and properly packed in the best and stable condition |

| Port | NINGBO |

| Supply Ability | |

| Supply Ability | 9999 Set/Sets per Month |

- Video

- Description

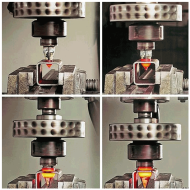

Solid Carbide Straight Shank C-Twist Drill - High-Speed Steel, Long Working Life, for CNC Applications

The lowly twist drill is one of the most commonly used tools in the machinist's arsenal. By all accounts, it also has some of the highest material removal rates of any of the tooling available. As such, it's worth getting to know them a little better.

Main Features

- Irregular or Rough Surface: Cut the feed back to as low as 1/4 the normal feedrate to avoid chipping the twist drill.

- Convex: Convex surfaces are hard to do unless the radius of the convex surface is greater than 4 times the drill diameter and you're entering perpendicular to the convex radius. If this is not the case, mill a flat spot for the drill to get started on before attempting to drill.

- Concave: Don't attempt a concave surface unless the radius is more than 15x the drill diameter and the drill is centered on the concavity and not the wall. You can drill the wall of a concave surface. Reduce feed to 1/3 when entering. If the surface doesn't meet these requirements, mill a flat before attempting to drill.

- Angled: Treat entry and exit of angled surfaces the same. If entering or exiting an angle surface of 2 to 5 degrees angle to the tip or less, reduce feed to 1/3 of normal to accomdate this interrupted cutting condition. For surfaces angled 5 - 10 degrees, ideally use a drill whose point angle matches the angle of the surface. If the angle is more than 10 degrees, you'll need to mill a flat before drilling.

- Reviews